I never thought we’d reach a point where motorcycles sport parts crafted by 3D printers, yet the future is here, and it’s roaring louder than a V-twin engine. Imagine zipping down the highway on a machine that’s partially molded from digital blueprints instead of traditional manufacturing. It sounds wild, but it’s happening.

The Rise of 3D Printed Motorcycles

3D printing, or additive manufacturing, has come a long way since the days of flimsy prototypes. Today, we’re talking about durable, tested components that can withstand the rigors of the open road. Cyclists are turning to this technology not just for its innovative edge, but also for customization and efficiency. The idea that a small garage could potentially build a bespoke motorcycle with parts made from a 3D printer sounds like something straight out of a sci-fi flick, doesn’t it?

The Big Players

You might be wondering, “Who’s actually putting 3D printed parts on the market?” Well, some pretty reputable names have entered the fray. For instance, BMW has dabbled in 3D printing to manufacture components for its motorcycles. Their innovative approach is not just about aesthetics; they’re using the technology to create lightweight but incredibly strong parts like brackets and frames for some of their models.

Then there’s Kawasaki, which introduced a limited-edition model that showcases a number of 3D printed components. The Kawasaki H2, known for its high performance, includes unique parts crafted through this method, reflecting their intent to push the boundaries of motorcycling technology.

Not Just the Big Boys

What’s fascinating is how this technology isn’t just restricted to the titans of the industry. Smaller manufacturers like the Italian bike company, CFMoto, are also integrating 3D printing into their craftsmanship. They produce unique design elements and potentially even entire motorcycles, making riding a customizable experience.

And let’s not forget custom builders. There are passionate individuals out there who are using 3D printing to push creativity to its limits. Meet the collaborative project from a group of bike enthusiasts who took a classic bike and infused it with modern technology using 3D printed parts for everything from custom fairings to ergonomic grips.

Benefits Beyond Aesthetics

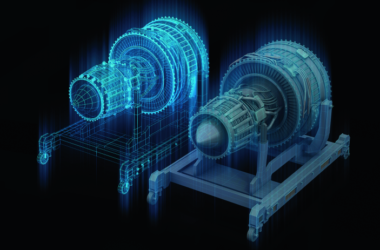

Now, I know what you’re thinking: “Are these parts really going to hold up out there?” Well, here’s the truth: it depends on the material used during printing. Advanced materials like titanium, carbon fiber, or certain polymers can create parts that rival metal in performance. And to be honest, the ability to create complex geometries means that parts can be lighter, which often leads to improved performance and fuel efficiency.

This innovation also allows for small production runs that don’t break the bank. Need a specialized bracket that’s no longer in production for your vintage bike? Just fire up the 3D printer and print your own. It’s a game-changer.

Venturing into the Future

You know what’s funny? Sometimes I imagine a world where instead of garage mechanics tinkering with wrenches, they’ll just be sitting in front of a computer designing their next custom part. The ability to share these designs across platforms means that enthusiasts can build upon one another’s work, leading to a vast community of creativity and collaboration.

Chances are, as this technology matures, we’re not just going to see individual parts but entire motorcycles being designed and assembled using 3D printing. I mean, why not? The racing leagues could even benefit from this, with lightweight and highly aerodynamic components that could potentially shave seconds off lap times.

FAQs About 3D Printed Motorcycles

Q: Are 3D printed parts safe for regular use?

A: Yes, as long as they are made from high-quality materials and properly tested.

Q: Can I customize my own motorcycle with 3D printing?

A: Absolutely! With access to a 3D printer and design software, the sky’s the limit for customization.

Q: How does 3D printing impact the cost of motorcycle production?

A: It can significantly reduce costs for small runs and custom parts, making unique builds more accessible.

So, are you ready to embrace the future? These motorcycles are more than just metal and rubber; they represent a leap into a new era of creativity and technology. While traditionalists may raise an eyebrow, I’m all in for a ride on a bike with 3D printed parts. It’s weird, it’s wild, and that’s exactly what makes it amazing.