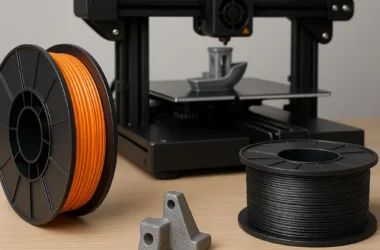

3D printing might sound like something out of a sci-fi movie, but it’s as real as the coffee on your desk. And just like your coffee, picking the right ingredients is key. Let’s dive into ABS filament, a popular choice for 3D printing enthusiasts and professionals alike.

What is ABS Filament?

ABS, or Acrylonitrile Butadiene Styrene, is a type of thermoplastic polymer. Now, before you tune out, stick with me. This stuff is fascinating! It’s the same material used in LEGO bricks and those tough-as-nails plastic parts on your car. Unlike your average garden-variety plastic, ABS is known for its strength, flexibility, and resistance to high temperatures. This makes it a favorite for creating durable and functional parts in 3D printing.

Features of ABS Filament

Durability and Strength

ABS filament is like the Chuck Norris of 3D printing materials. It’s tough, strong, and can withstand a fair amount of wear and tear. This makes it ideal for printing objects that need to take a beating, like tool handles, toys, and automotive parts.

Heat Resistance

If your print is going to be exposed to heat, ABS is your go-to filament. It can handle higher temperatures without melting down into a sad puddle of plastic. This feature makes it perfect for items like car cup holders or other automotive parts that might get a little toasty.

Flexibility

ABS is not just all about brute strength; it’s got a flexible side too. This flexibility makes it suitable for items that need to bend a little without snapping, like plastic hinges or phone cases.

Smooth Finish

When it comes to aesthetics, ABS stands out with its smooth, shiny finish. This makes it an excellent choice for printing objects that need to look good, like figurines or prototypes.

Benefits of Using ABS Filament

Why should you choose ABS over other filaments like PLA or PETG? Well, let me spill the beans.

Cost-Effectiveness

ABS is generally cheaper than many other 3D printing materials. If you’re churning out a lot of prints, this can save you a pretty penny. Plus, its durability means you won’t have to reprint broken items as often, which is a win-win!

Post-Processing Ease

ABS loves a good acetone bath. Post-processing with acetone vapor can give your prints a glossy finish and smooth out any layer lines. It’s like giving your print a day at the spa.

Recyclability

For those who love the planet as much as they love 3D printing, ABS can be recycled. While it’s not as biodegradable as PLA, finding recycling programs that accept ABS can help reduce your environmental footprint.

Wide Range of Applications

ABS is versatile. From household items to prototype parts and even cosplay props, the possibilities are almost endless. If you can dream it, you can probably print it with ABS.

Tips for 3D Printing with ABS Filament

Printing with ABS isn’t always as easy as pie. It can be a bit finicky, but with these tips, you’ll be an ABS-printing pro in no time.

Use a Heated Bed

ABS has a tendency to warp as it cools. Using a heated bed helps keep the base of your print warm, reducing the chances of warping and ensuring your print sticks to the bed. Think of it as a cozy blanket for your print job.

Enclosure is Key

Print in an enclosed space to maintain a stable temperature around your print. Drafts and temperature fluctuations are the enemies of ABS, causing warping and cracking. An enclosure helps keep the temperature consistent, giving your print the best chance of success.

Proper Ventilation

ABS emits fumes when heated, and while it’s not going to knock you out like a bad smell, it’s best to print in a well-ventilated area. An open window or a small fan can help disperse the fumes, keeping your workspace fresh.

Experiment with Bed Adhesion

Getting ABS to stick to the print bed can sometimes feel like trying to put a cat in a bath. Using adhesives like ABS slurry, glue stick, or painter’s tape can improve bed adhesion and reduce the risk of prints coming loose mid-job.

Tweak Your Print Settings

Every 3D printer is different, and what works for one might not work for another. Don’t be afraid to experiment with settings like print speed, layer height, and extrusion temperature to find what works best for your specific setup.

Common Challenges and Solutions

3D printing with ABS can be like a roller-coaster ride—thrilling, with a few unexpected twists. Here are some common challenges and how to tackle them:

Warping

Warping is like the evil twin of 3D printing. To combat it, ensure your bed is heated properly and your enclosure maintains a stable temperature. Consider using a brim or raft to increase bed adhesion.

Cracking

If your prints are cracking, it’s likely due to temperature fluctuations. Make sure your enclosure is doing its job, and try reducing the layer cooling fan speed. This keeps the filament warmer for longer, allowing it to bond better.

Stringing

Nothing ruins a print like strings of filament spider-webbing across your masterpiece. To reduce stringing, tweak your retraction settings and make sure your nozzle is clean. Lowering the print temperature slightly can also help.

ABS vs. Other Filaments

ABS isn’t the only filament in town. Let’s take a quick look at how it stacks up against some other popular choices:

- PLA: Easier to print and more environmentally friendly, but not as durable or heat-resistant as ABS.

- PETG: Offers a good middle ground between PLA and ABS with decent strength and flexibility, but requires specific print settings and can be tricky to dial in.

- Nylon: Extremely strong and flexible, but challenging to print due to its high moisture absorption and need for high temperatures.

Key Takeaways

ABS filament is like the Swiss Army knife of 3D printing materials. It’s strong, versatile, and with the right approach, can produce some truly amazing prints. Sure, it has its quirks, but with a little patience and practice, you’ll be printing ABS like a pro. So, grab your favorite filament, fire up that 3D printer, and let your creativity run wild!