Introduction to 3D Printing and Materials

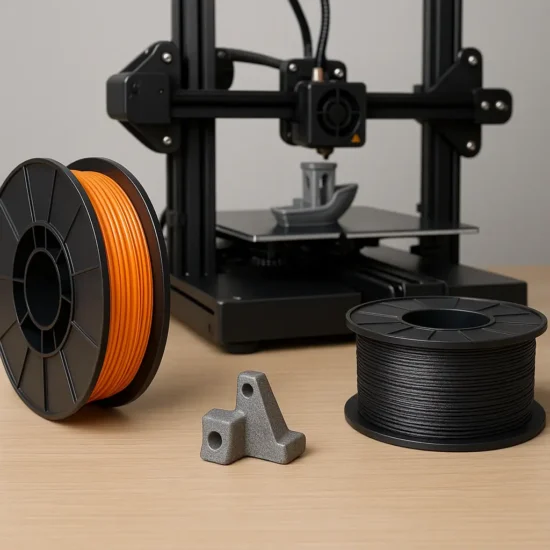

Ah, 3D printing! That magical world where your wildest ideas can be transformed into tangible objects right before your eyes. If you’ve ever watched in awe as a printer layers material to create everything from tiny figurines to functional prototypes, you know how exciting this technology can be! But amid all this excitement, there’s one crucial aspect that can’t be overlooked: materials.

Choosing the right material for your 3D printing project can make all the difference in the quality, durability, and overall success of your prints. This guide will walk you through the various materials used in 3D printing, their distinct properties, advantages and disadvantages, and how to choose the best fit for your specific projects. Buckle up — we’re about to dive into the nitty-gritty of 3D printing materials!

Types of 3D Materials

Materials used in 3D printing can be broadly categorized into three types: thermoplastics, metals, and composites. Each of these categories has its own set of characteristics that can make them ideal (or not so ideal) for certain applications.

Thermoplastics

Thermoplastics are the bread and butter of the 3D printing world, especially when it comes to FDM (Fused Deposition Modeling) printers. These materials can be melted and re-melted, which makes them easy to work with and highly versatile.

Popular Types: PLA, ABS, PVA, Nylon, and HDPE

-

PLA (Polylactic Acid)

-

Properties: Biodegradable, easy to print, low warping.

-

Applications: Prototyping, toys, decorative items.

-

Advantages: Safe, environmentally friendly, and available in many colors.

-

Disadvantages: Limited heat resistance; can be brittle over time.

-

ABS (Acrylonitrile Butadiene Styrene)

-

Properties: Strong and impact-resistant, higher melting point than PLA.

-

Applications: Functional parts, automotive components, toys (like LEGO!).

-

Advantages: Can withstand higher temperatures, more durable.

-

Disadvantages: Emits fumes during printing, can warp without proper settings.

-

PVA (Polyvinyl Alcohol)

-

Properties: Water-soluble filament, used mainly as support material.

-

Applications: Creating complex geometries that require support.

-

Advantages: Dissolves in water, making clean-up easy.

-

Disadvantages: Expensive compared to standard filaments, limited to specific applications.

-

Nylon

-

Properties: Strong, flexible, resistant to wear and chemicals.

-

Applications: Functional parts like gears, hinges, and tools.

-

Advantages: Excellent layer adhesion and durability.

-

Disadvantages: Can be difficult to print due to warping and requires a high-temperature printer.

-

HDPE (High-Density Polyethylene)

-

Properties: Tough, lightweight, and resistant to moisture.

-

Applications: Containers, bottles, and marine applications.

-

Advantages: Durable and semi-flexible.

-

Disadvantages: Can be challenging to adhere properly to the build plate; not as popular in the 3D market.

Metals

When it comes to metal 3D printing, we step up the game considerably. Metals can be quite different from everyday plastics, and they are typically used in specialized industrial applications.

Applications in Industries:

- Aerospace: Where weight savings and structural integrity are paramount.

- Automotive: Permanent part production and prototyping for components that require high durability.

- Medical: Custom implants and prosthetics made with precision.

Properties and Features:

- Stainless Steel: Known for its corrosion resistance, making it ideal for tools and industrial parts.

- Titanium: Exceptional strength-to-weight ratio, commonly used in aerospace and medical applications.

- Aluminum: Lightweight and ideal for creating functional prototypes.

Generally, metal 3D printing involves processes like DMLS (Direct Metal Laser Sintering) or EBM (Electron Beam Melting), and it requires specialized equipment, meaning it’s not usually accessible for hobbyists.

Composites

Composite materials bring together the best of both worlds by combining plastic filaments with other materials to enhance their properties.

Examples and Areas of Application:

- Carbon Fiber Reinforced Filament: This is primarily used in high-performance parts that require extra strength without adding too much weight.

- Glass-Filled Filaments: These provide excellent durability and impact resistance while remaining lightweight.

Advantages and Disadvantages:

- Advantages: Composites often yield parts that are stronger and lighter than their pure plastic counterparts.

- Disadvantages: They can be more challenging to print due to abrasive fibers that may wear out nozzles faster.

Comparison of FDM, SLA, and SLS Materials

Different 3D printing technologies make use of various materials and processes. Here’s a handy comparison table that highlights the differences and common uses among FDM, SLA (Stereolithography), and SLS (Selective Laser Sintering) materials:

| Material Type | FDM (Fused Deposition Modeling) | SLA (Stereolithography) | SLS (Selective Laser Sintering) |

|---|---|---|---|

| Common Materials | PLA, ABS, PETG, Nylon | Liquid resin (various types) | Nylon, metals, elastomers |

| Applications | Prototypes, functional parts, models | High-detail models, dental and jewelry applications | Functional parts, prototypes for production |

| Surface Finish | Moderate | Excellent | Good |

| Ease of Use | Easy | Moderate | Moderate to Difficult |

| Cost | Low | Moderate to High | High |

Pros and Cons of Various Materials

When weighing your options, it’s important to consider the advantages and disadvantages of each material type. Below are the pros and cons broken down for better understanding.

Thermoplastics: Pros and Cons

Advantages:

- Wide accessibility and affordability.

- A large variety of materials with various properties and colors.

- Easy to adjust print settings for optimal results.

Disadvantages:

- Limited thermal resistance depending on the material.

- Some materials may warp, especially during cooling.

Metals: Pros and Cons

Advantages:

- Exceptional structural integrity and functional performance.

- Suitable for high-stress applications in industries like aerospace and medical.

Disadvantages:

- High cost and specialized equipment requirements.

- A steep learning curve and less flexibility with designs compared to plastic.

Composites: Pros and Cons

Advantages:

- Enhanced mechanical properties compared to standard filaments.

- Overall lighter and stronger components for specialized applications.

Disadvantages:

- More expensive and can require specific printers capable of handling abrasiveness.

- Some composites might need careful handling to prevent nozzle wear and damage.

How to Choose the Right Material for Your Project

Choosing the right material can feel overwhelming, so let’s break it down into manageable steps:

-

Define the Purpose: What do you intend to create? Is it something purely for display, or does it need to hold weight and be functional?

-

Consider the Environment: Will the printed object be exposed to high temperatures, moisture, or chemicals? Choose materials accordingly.

-

Evaluate the Budget: How much are you willing to spend? Remember that some materials, particularly metals and composites, can be on the pricier side.

-

Check Availability: Some materials might not be easily accessible, so confirm you can procure them before starting your project.

-

Assess Your Machine: Ensure that the printer you’re using is compatible with the materials you wish to work with.

Future Developments in 3D Materials

The world of 3D printing materials is rapidly evolving, and as technology advances, we can expect some fascinating trends:

-

Sustainable Materials: The trend towards eco-friendly alternatives continues to rise, with materials derived from renewable resources gaining popularity.

-

Smart Materials: Imagine materials that can adapt to their environment, changing properties upon exposure to temperature or light. This innovation could revolutionize design functionality.

-

Metal Fusion Advancements: New techniques like binder jetting are emerging, making metal printing more accessible.

The future of 3D printing materials is promising, and as innovations roll out, there will be even more possibilities for what we can create.

Conclusion

With the information laid out here, you should now have a comprehensive understanding of various 3D printing materials. From thermoplastics that are easy to use and cost-effective to the strength and durability of metals and the unique properties of composites, there’s a lot to consider.

Choosing the right material not only impacts the functionality of your project but can also save you time and money in the long run. So, take the time to evaluate your needs and experiment with different materials. The world of 3D printing awaits — let your creativity take flight!

FAQ

How do materials affect the quality of 3D printing?

Materials impact factors such as finish quality, structural integrity, flexibility, and overall durability of the final print.

What materials are most popular in home 3D printing?

PLA and ABS are among the most popular due to their accessibility, ease of use, and wide range of applications.

What should I consider when choosing a material?

Consider the intended use, environmental exposure, budget constraints, and compatibility with your 3D printer while making your selection.