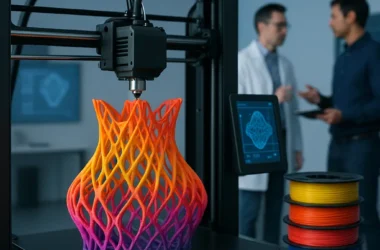

It sounds crazy, but the future of 3D printing just got a serious upgrade. If you’ve ever marveled at the intricate designs a 3D printer can produce, only to be thwarted by the limitations of time and labor, you’re in for a treat. Meet the Virginia Tech Design Team, who’s pulled off something genuinely groundbreaking: an automated plate swapper for continuous 3D printing. No more waiting around for prints to finish before you can start your next project. Instead, you can kick back and let the machine do the heavy lifting.

What is the Automated Plate Swapper?

Okay, let’s break it down. This innovative gadget is designed to automatically remove a completed print off the print bed and replace it with a new, blank plate, all while the printer is still running. Imagine getting that perfect model done, only to realize that you have to spend time removing it, cleaning the plate, and starting the whole process over. With this system, you can save hours of manual work and keep the creative process flowing.

How It Works

Now, I know what you’re thinking: how does this even work? It’s a combination of clever design and tech-savvy automation. The plate swapper uses a series of robotic arms that gently lift the finished print and slide it off, seamlessly placing a new plate into position for the next job. It’s like an automated assembly line for your creative projects.

The design team at Virginia Tech has gone to great lengths to ensure precision. From sensors that detect when a print is completed to mechanisms that stabilize the printer during the swap, every element has been carefully crafted. It genuinely makes me wonder why no one thought of this sooner!

Implications for the 3D Printing Industry

You might be asking yourself—why should I care about this? Well, the implications are huge. For hobbyists and professionals alike, this means far less downtime and a lot more productivity. Imagine being able to multi-task: starting a print, working on your computer, and not having to jump back to babysit the printer every hour. For businesses that rely on 3D printing, such as prototyping firms or low-volume manufacturers, this could translate into significant cost savings and faster turnaround times.

A Savvy Move for Education

Even in educational settings, this technology could revolutionize the way students engage with design and engineering projects. Picture this: a classroom filled with students eager to get their hands on 3D printing technology, but often limited by time constraints. An automated plate swapping system would elevate the learning experience, allowing for more exploration, experimentation, and mastery of digital fabrication tools.

To be honest, it’s just exciting to think about all the possibilities this opens up—from massive production runs to experimental art projects where the only limitation is imagination.

What’s Next?

So, what’s next for this automated wonder? It’s still in the experimental stages, but the Virginia Tech team has big dreams. They’re looking at refining the technology for commercial use, ensuring that it not only works flawlessly but is also accessible for various budgets. Try imagining this in your garage or workshop, humming away as you work on your next masterpiece.

FAQs

Is the automated plate swapper compatible with all 3D printers?

Not all printers are created equal. Currently, the technology is designed for specific models, but the goal is to broaden compatibility in future iterations.

What materials can be used?

Most common 3D printing materials like PLA and ABS should work without a hitch, but details on material compatibility will be refined as the project develops.

When will this technology be available to the public?

That’s still up in the air, but keep an eye on Virginia Tech’s announcements. The aim is to make this technology as widely usable as possible!

For anyone who’s passionate about 3D design, it feels like we’re on the brink of something monumental. The automated plate swapper could change the way we think about creation in a world that’s always in need of innovation. I don’t know about you, but I’m ready for a future where printing takes care of itself!