Have you noticed how everything can be 3D printed these days? From toys to houses, the sky seems the limit. But what about weapons? Yes, you heard right – weapons! In a world where “Did you 3D print this?” has become the new “Did you buy this from IKEA?”, it raises questions about the limits of technology.

Historical Context: It all started not too long ago when the first 3D printed gun was able to fire a shot. And no, this is not a sci-fi movie script. Since then, society and governments have been trying to catch up with technology, trying to figure out how to live with it. And it looks like they will catch up!

Technical Aspects: Creating weapons with a 3D printer is like magic. Well, if Harry Potter had decided to become an engineer instead of doing magic. But instead of a magic wand, we have CAD files and plastic. What about the materials? They range from “almost as durable as your baby tooth” to “can withstand a little more than the glare of a disappointed mother.”

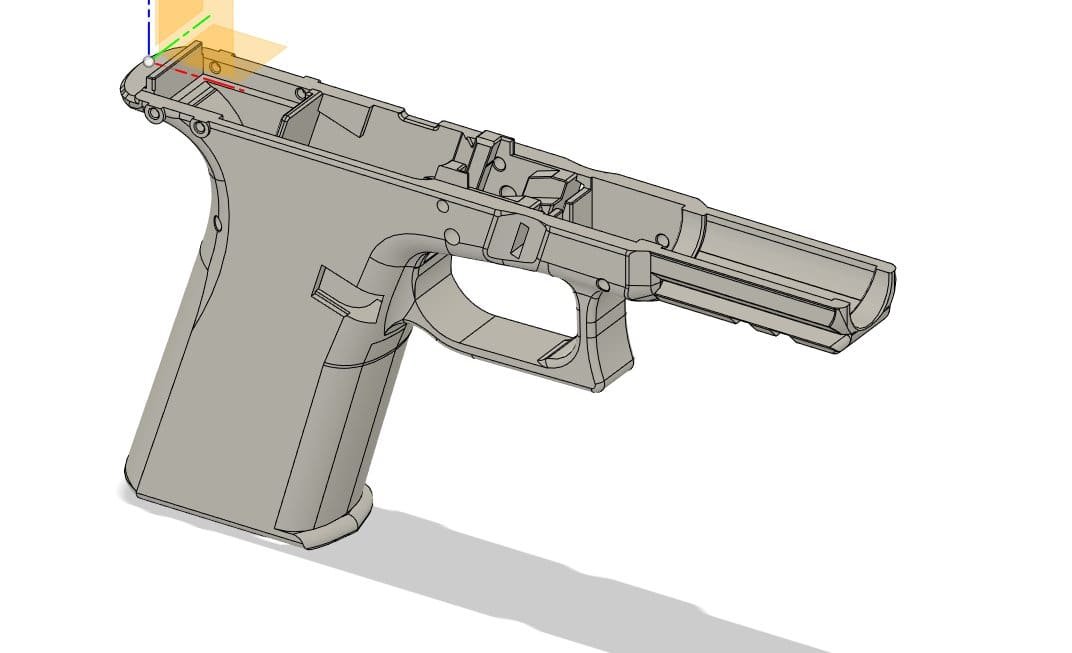

Creating a weapon using 3D printing involves several key steps, from design to physical printing and subsequent assembly. It is important to note that gun manufacturing, including 3D printing, may be illegal or highly regulated in many countries, and local laws must always be followed.

- Designing a 3D model

The first step is to create or obtain a 3D model of the weapon. This can be done using specialized 3D modeling software such as AutoCAD, Fusion 360, SolidWorks or Blender. The model must be carefully designed, taking into account all mechanical and functional aspects of the weapon, including mountings, trigger mechanism and bore. - Preparation for printing

Once the 3D model is created, the file is prepared for printing using special software called a print preparation tool (slicer). This program breaks down the 3D model into layers and generates instructions (G-code) for the 3D printer, including printing parameters such as print speed, temperature and infill. - Material selection

Plastic materials such as ABS (acrylonitrile butadiene styrene) or PLA (polylactide) are most commonly used to print guns, although some parts may require more durable or specialized materials. The choice of material will depend on the requirements for strength, flexibility and durability of the finished product. - Printing

The next stage is 3D printing itself. The printer deposits sequential layers of molten material following G-code instructions, gradually creating a physical object from the model. The process can take anywhere from a few hours to a few days, depending on the size, complexity and print settings. - Post-processing

Once printing is complete, the product usually requires some post-processing. This may include removing support structures, sanding, polishing or painting to improve appearance and functionality. - Assembly and testing

If the weapon consists of several parts, the last step is to assemble them. After assembly, it is important to thoroughly test the weapon in a safe environment to ensure it is reliable and safe to use.

Creating guns using 3D printing is a complex process that requires careful planning, attention to detail, and extensive knowledge of 3D printing and gunsmithing. Responsible handling and legal compliance are key aspects when dealing with such projects.

So, let’s talk where to start!

3D printers

3D printing weapons requires specialized models that can work with durable materials. However, it’s worth noting that creating weapons with 3D printers raises serious legal and ethical questions and may be illegal in many countries. It is always important to know and comply with local laws in this matter, but more on that later!

In terms of technology, here are some examples of 3D printers that can be used to work with more durable materials, such as metals or durable plastics, which may be suitable for creating certain weapon components:

- The Markforged Mark Two is an industrial 3D printer that can print carbon fiber, fiberglass, nylon and other composite materials. Prices can start at $13,000.

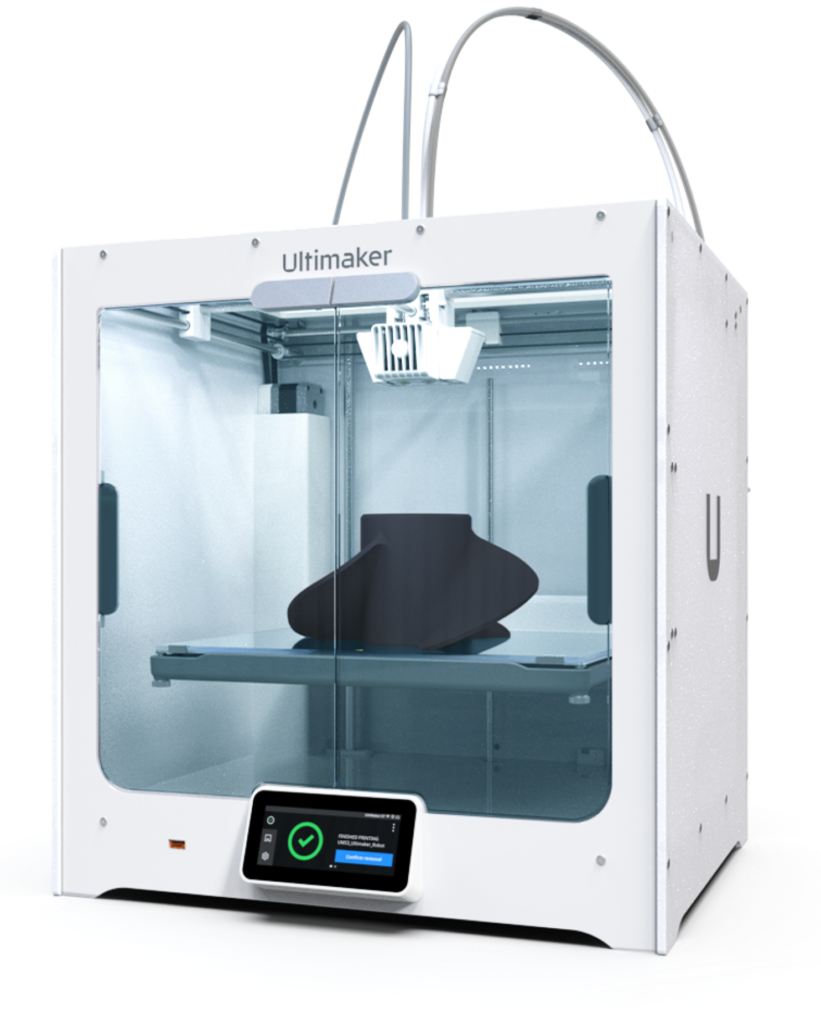

- Ultimaker S5 is a high-quality 3D printer that works with a wide range of plastics, including nylon and reinforced materials. The price varies between 6,000 US dollars.

- The EOS M 290 is a direct metal laser sintering (DMLS) printer designed for the production of high-quality metal products. Prices for such cars start from several hundred thousand dollars.

While these printers can be used to create some weapon components, it is important to remember that the quality and safety of homemade weapons can vary greatly and can be dangerous. In addition, creating weapons without the appropriate permits can lead to serious legal consequences.

And remember, if your 3D printer asks why it needs to print so many parts, it’s better to answer that it’s an “office paper clip improvement project” rather than something illegal!

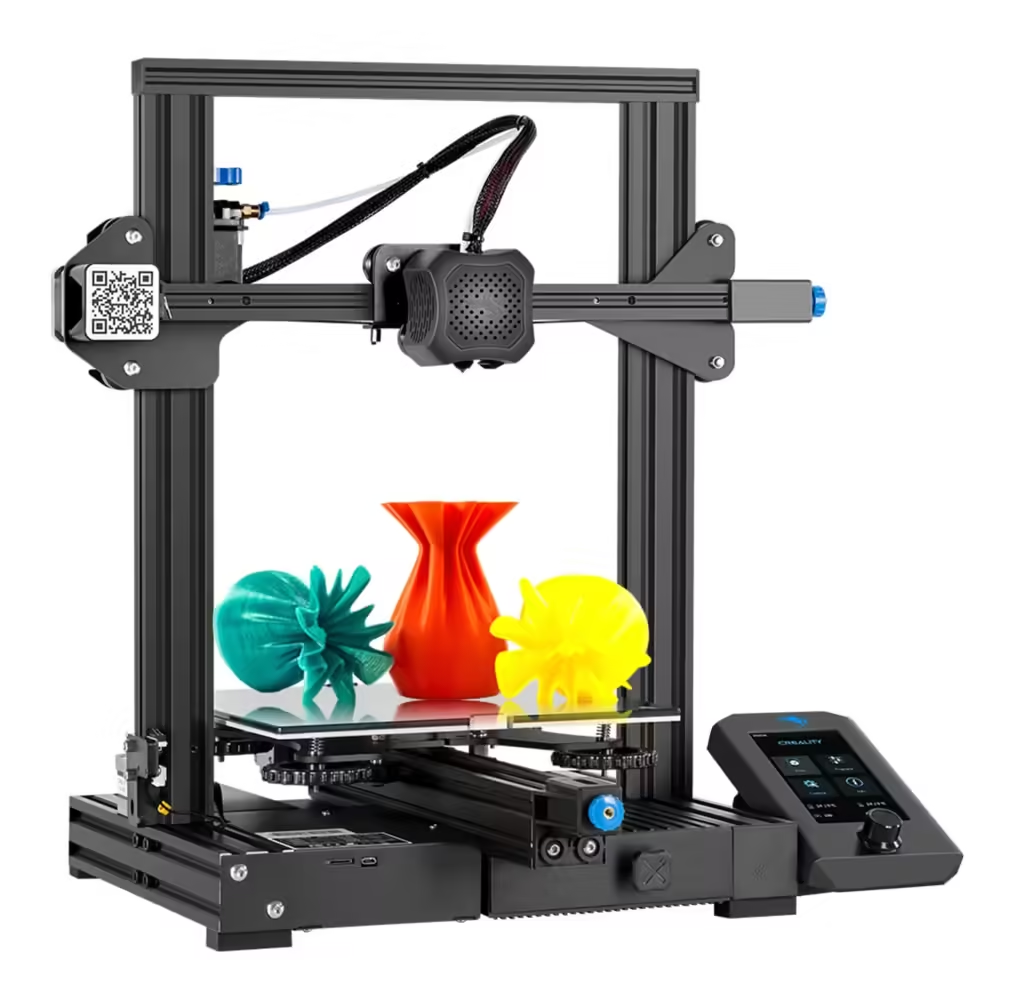

Creality Ender 3 V2

To start with a cheap 3D printer, you might consider the Creality Ender 3 V2. This is one of the most popular and affordable options on the market, suitable for beginners but still robust enough for more advanced projects.

Where can I buy

3D printing materials can be purchased from specialty stores or online trading platforms such as Amazon, eBay, AliExpress, or local electronics and hobby stores.

Materials

- For the Ender 3 V2, it is best to use PLA (polylactide) due to its ease of printing and availability. PLA is a biodegradable material made from renewable resources such as cornstarch. It features good detail, ease of printing and low shrinkage, making it an ideal choice for beginners.

- ABS (acrylonitrile butadiene styrene) can also be used for stronger and heat-resistant parts, but it requires higher printing temperatures and good ventilation due to the release of vapors.

Price

- Creality EnderCreality Ender 3 V2 itself will cost about $200-300 depending on the delivery

- The price of a roll of PLA filament (1 kg) usually ranges from $20 to $30, again depending on the brand and

When choosing a 3D printer and materials, always consider your project and part requirements. Remember that even a cheap 3D printer can work wonders in the right hands.

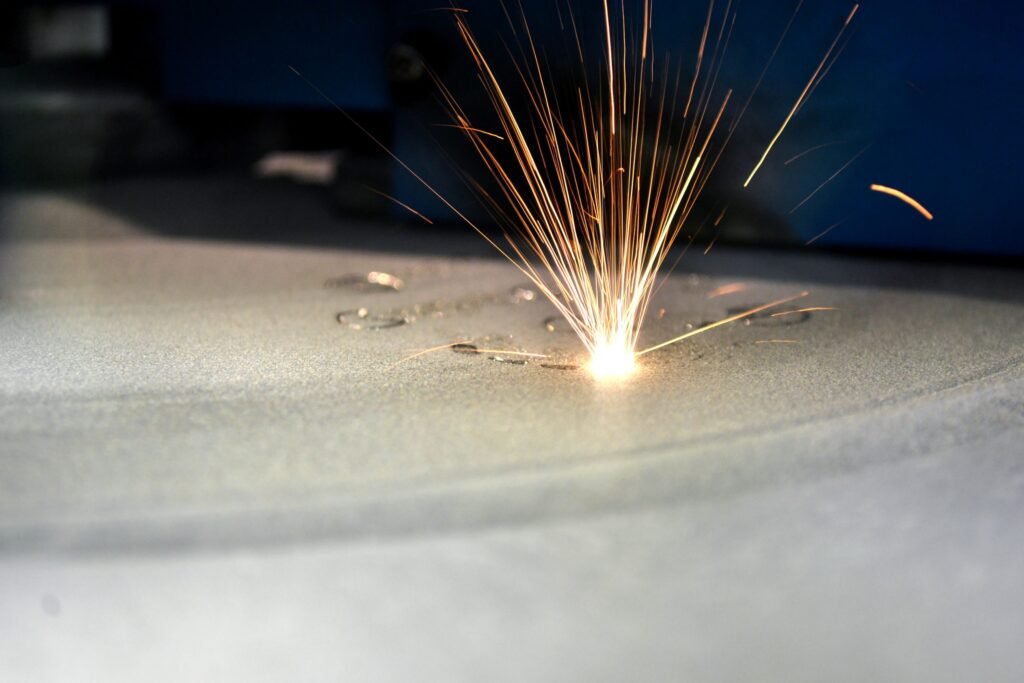

EOS M 290

Metal 3D printing requires more complex and expensive machines, such as direct metal laser sintering (DMLS) or laser stereolithography (SLA) printers. One of the leading models in this category is the EOS M 290.

Where can I buy

Metal powders for 3D printing can be purchased directly from 3D printer manufacturers or from specialized 3D printing material suppliers. Powder quality is critical to successful printing, so it is recommended to purchase materials from trusted and reliable suppliers.

Materials

- Printers like the EOS M 290 can use a variety of metal powders, including stainless steel, aluminum, titanium, cobalt-chromium alloys and many others. The choice of material depends on the requirements for the final product, including strength, flexibility, heat resistance and other properties.

Price

- is a high-tech industrial piece of equipment and can cost several hundred thousand dollars depending on configuration and included features.

- Prices for metal powders can also vary significantly depending on the material; for example, titanium powder will usually cost more than stainless steel powder. The estimated cost can start from several tens of dollars per kilogram and reach several hundred for more expensive alloys.

Investment in such equipment and materials is usually worthwhile for the production of high-precision metal parts in the aerospace, medical, automotive and other industries that require complex components with high strength and durability requirements. When purchasing such equipment, it is important to consider not only the initial purchase costs, but also the costs of maintenance, materials, and personnel training.

Estimating the cost of printing, for example, a pistol on a 3D printer depends on many factors, including materials, design complexity, and the strength and durability requirements of the final product. It should be noted that 3D printing weapons may be illegal in many countries and may have serious legal consequences. Always check local laws and regulations before starting such projects.

On a plastic 3D printer

On a simple plastic 3D printer like the Creality Ender 3 V2, the main expense will be the cost of PLA or ABS filament. Printing a simple gun may require about 0.5-1 kg of filament.

- Filament cost: $20-$30 per kg, depending on the quality and type of material.

- Total cost: Approximately $10-$30, considering that not all kilograms of filament will be used.

On a metal 3D printer

For metal 3D printing using a printer like the EOS M 290, costs increase significantly due to the cost of metal powders and machine running costs.

- Metal powder cost: Can range from $50 per kg for simpler materials to several hundred dollars per kg for more expensive alloys.

- Operating costs: Includes electricity, equipment wear and tear, maintenance, etc.

- Total Cost: It is very difficult to accurately estimate without specific project details, but can start from a few hundred to several thousand dollars, given the high cost of metal powders and equipment maintenance.

These estimates assume that you already have access to an appropriate 3D printer. Purchasing your own equipment will add significant additional costs. It is also worth considering that 3D printed plastic weapons may not withstand even one shot and can be extremely dangerous for the user. Metal 3D printed guns can be more reliable, but their creation requires significant knowledge and experience in 3D printing and gunsmithing.

A reasonable question arises: Where can I get a model for printing?

To print objects, including guns, on a 3D printer, you need to start with a 3D model of the object, which is usually in a file format such as STL or OBJ. It’s worth noting that 3D printing guns is a legal and ethical issue that is highly regulated in many countries, and may be illegal or require special permits.

Where to get a model

- Create your own file: If you have skills in 3D modeling software such as Autodesk Fusion 360, Tinkercad, SolidWorks or Blender, you can design the 3D model yourself. This will allow you to have full control over the design and adapt it to your needs.

- Purchase or download ready-made files: There are platforms such as Thingiverse, GrabCAD or Turbosquid where users share their 3D models. Some offer files for free, while others may require a purchase. However, in the case of weapons, their models may not be available due to the above-mentioned legal restrictions.

- Turning to Professionals: If you do not have the ability or desire to create your own models, you can turn to professional 3D designers or engineers who will provide services for creating custom 3D models. This may be a more expensive option, but it provides a high-quality, dedicated model.

Who can create the file:

- 3D Designers and Engineers: Professionals with experience in 3D modeling and engineering software can create complex and accurate 3D printable models.

- Hobbyists and Enthusiasts: With the rise in popularity of 3D printing, many hobbyists have learned the basics of 3D modeling and can create simple to moderately complex models.

What will jurisprudence tell us? This is an important question!

Legal and ethical issues related to 3D printing weapons are becoming more pressing as technology advances. These aspects include both legal restrictions and ethical dilemmas.

Legally

Legislation regarding 3D printing of guns varies by country and region. In many cases, existing gun control laws are not fully adapted to the challenges presented by 3D printing.

- USA: In the United States, federal law requires that any gun produced must contain enough metal to be detected by a metal detector, which includes 3D printed guns. Also, transferring weapons without proper checks and registrations may violate the law.

- European Union: Europe also has strict restrictions on gun production and ownership that apply to 3D printed guns. Regulation varies between member countries.

- Australia, UK, Japan and other countries: The introduction of laws specifically aimed at combating the proliferation of 3D printed weapons indicates growing concern among governments around the world regarding this issue.

Ethical

The availability of 3D printed weapons raises a number of ethical questions, especially in the context of safety, liability and control.

- Affordability: The ability to easily print guns at home could greatly increase the availability of firearms, raising concerns about increased crime and accidents.

- 3D-printed plastic guns may be more difficult to detect by standard security methods, posing public safety risks at airports, schools and other locations.

- Intellectual Property and Distribution: The proliferation of gun print files on the Internet calls into question who is responsible for their use and how access to such information can be controlled or limited.

- There is a debate about the moral responsibility of 3D printer manufacturers and software developers for how their products are used, including in the production of weapons.

Discussion and policy development on 3D printing of weapons requires a balanced approach that takes into account innovation and freedom to experiment, as well as the need to ensure public safety and compliance with the law. This is a complex and multifaceted issue that requires attention from both legislators and society as a whole.

There is also a dangerous side to the issue; there are always risks!

Dangers

3D printing weapons poses a number of dangers and risks, both for individuals and for society as a whole. Here are some of the key dangers:

Unreliability and security

- Unpredictable Quality: Due to the variable quality of 3D printing, especially when using home 3D printers and non-specialized materials, there is a risk of the weapon breaking during use, which could result in injury or death to the shooter or others.

- Lack of Standards: Unlike traditionally manufactured guns, 3D printed guns lack uniform quality and safety standards, increasing the risk of malfunctions and accidents.

Illegal distribution and use

- Availability: The ability to print guns at home makes them easier to distribute illegally and make them available to those prohibited by law from owning guns, including criminals and terrorists.

- Untraceable: 3D printed guns often do not have serial numbers and may be manufactured without any registration, making them difficult for law enforcement to identify and track.

Technological and legal challenges

- Legislative circumvention: 3D printing technology can circumvent existing legal restrictions on the production, purchase and possession of weapons, creating gaps in law enforcement.

- Regulatory Complexity: The rapid development of 3D printing technology and its widespread availability pose challenges for governments to develop and implement effective regulation.

- Impact on Public Safety: The ability to mass produce weapons using 3D printing could have a negative impact on public safety and levels of violence in the community.

In light of these dangers, it is important for legislators, law enforcement and society at large to strike a balance between innovation and technological progress on the one hand and public safety and legal standards on the other. This requires constant analysis of the developing situation and adaptation of legislation to new challenges.

Well, in conclusion, the main points of everything said above!

Basic moments

- Technological capabilities: 3D printing allows the creation of complex objects with a high degree of customization, including weapons. This calls into question traditional methods of controlling the production and distribution of weapons.

- Legal and Ethical Challenges: Existing legislation often fails to keep pace with rapid advances in technology, creating legal gaps and ethical dilemmas, especially regarding liability for the misuse of 3D printed guns.

- Dangers and Consequences: 3D printing guns poses a number of risks, including unreliable products, illegal distribution, bypassing gun controls, and a possible increase in violent crime.

Future and regulation

- Adapting Legislation: It is important to develop and implement legislation that can adapt to rapidly changing technologies while ensuring effective controls over the production and proliferation of weapons.

- International Cooperation: Given the global nature of the Internet and the availability of 3D printing technologies, it is important to promote international cooperation in the field of gun regulation and control.

- Education and Awareness: Raising awareness of the dangers and legal implications of 3D printing guns can help reduce their illegal use. The role of education in the ethical use of technology is also important.

- Technology Solutions: The development and implementation of technology solutions, such as embedded identification and tracking mechanisms in 3D printed products, can help combat the proliferation of illegal weapons.

The future of 3D gun printing will depend on the balance between innovation and regulation, and the ability of society and lawmakers to adapt to new technological realities while ensuring safety and rights.

Wrapping Up

Let’s recap our journey through the world of 3D gun printing with a touch of humor.

First, we learned that 3D printing can be used to create almost anything, from cat earrings to… well, guns. It turns out that if you have a 3D printer and the Internet, then the possibilities are almost endless. But remember, just because youyou can 3D printing a gun doesn’t mean it’sneed to do.

We discussed that while the technology is impressive in its capabilities, printing guns is not the best idea for a home hobby. Not only because your cat may not appreciate the sudden change in your craft, but also because of the heaps of legal, ethical and safety pitfalls that may lie in wait for you.

Governments and the public at large are not keen on the idea of anyone with access to the internet and a 3D printer printing guns in the comfort of their basement. It turns out there is such a thing as “laws” and they take this issue quite seriously.

Plus, if you think building guns on your desk is the pinnacle of DIY culture, think again. In addition to the legal consequences, there are also physical risks associated with homemade weapons, which can explode in your hands at the most inopportune moment. At the very least, it can ruin your day.

So here's a tip: if you want to print something with your brand new 3D printer, make something less controversial. Maybe a stylish pot for your cactus? Or even a cool smartphone stand that will definitely not let you down and will not lead to unwanted attention from law enforcement agencies. But seriously, let's use amazing technology responsibly and to create something that makes the world a better place rather than adding problems to it.