Friends! Surely you have had questions about what can be done with a 3D printer and how you can work with it! I think this article will help you get a little closer to this miracle of modern technology!

First, a little information, so to speak for simple reference!

What is 3D Printing?

3D printing is a radical tool that is changing many aspects of modern creativity and production, providing the ability to create objects as complex as never before. Here are some key ways people use 3D printers:

- Rapid Prototyping: The ability to quickly and cheaply create prototypes using 3D printers will change the way products are developed in most industries, allowing designers and engineers to test their ideas and quickly tweak them at an early stage.

- Customization: 3D printing has the ability to create customized products with unique designs and personal preferences, which is very valuable in the jewelry and fashion industries.

- On-site Production: This means that parts and components are manufactured locally, saving on logistics and inventory costs. This application is used in the aerospace and defense sectors.

- Medical Use: From prosthetics and implants to printed organs and tissues, 3D printing is expanding medical horizons in this regard by providing effective and cost-effective means.

- Education and Research: In educational institutions and research centers, 3D printers are used to visually teach complex concepts and conduct experiments, and they promote in-depth understanding of the subject.

- Arts and Culture: Artists and designers are using 3D printing to create expressively unique works of art, exploring new forms and materials that contribute to the development of contemporary art.

Great! Great technology for all occasions! Now the most interesting part – about the materials for working with this miracle of high technology!

Materials for 3D Printing

3D printing allows the use of a variety of materials depending on the item being manufactured and the required characteristics. Here are the materials commonly used in various fields:

- Toys:

- Plastics: ABS (acrylonitrile butadiene styrene), PLA (polylactide), PETG (polyethylene terephthalate glycol-modified) for strength and safety.

- Flexible materials: TPU (thermoplastic polyurethane) to create flexible parts.

- Building Construction:

- Concrete mixtures: Specialized concrete mixtures for 3D printing with additives that improve fluidity and hardening time.

- Composite materials: Blends with polymers and fibers to improve strength characteristics.

- Food:

- Food pastes: Chocolate, fruit and vegetable purees, dough, meat and fish pastes, formed for 3D printing.

- Weapons:

- High-strength plastics: ABS and Nylon for creating housings and load-bearing parts.

- Metals: Steel and titanium for printing more critical and loaded components in firearms.

- Car Parts:

- Plastics: ABS, PLA, PETG for non-structural parts and prototypes.

- Metals: Aluminum, titanium for the manufacture of engine and body parts.

- Medical Applications:

- Polymers: PLA, ABS, PEEK (polyetheretherketone) for prosthetics and orthopedic products.

- Biocompatible materials: Hydrogels and special polymers for bioprinting of tissues and organs.

- Clothes and Accessories:

- Flexible materials: TPU, silicone mixtures for shoe printing.

- Polymer threads: PLA, Nylon threads for 3D printing of fabrics and clothing items.

These materials are selected based on the required properties of the products, such as strength, flexibility, temperature resistance, and compatibility with the human body, as well as the ability to be processed by 3D printers.

Well, just to give you an idea of what kind of printer you can buy!

Choosing a 3D Printer

Yeah, are you already interested? Well, let’s add a little clarification!

The 3D printer market offers a wide selection of models that differ in functionality, print quality, and, of course, price. Here are some examples of 3D printers that can give an idea of the current state of the market:

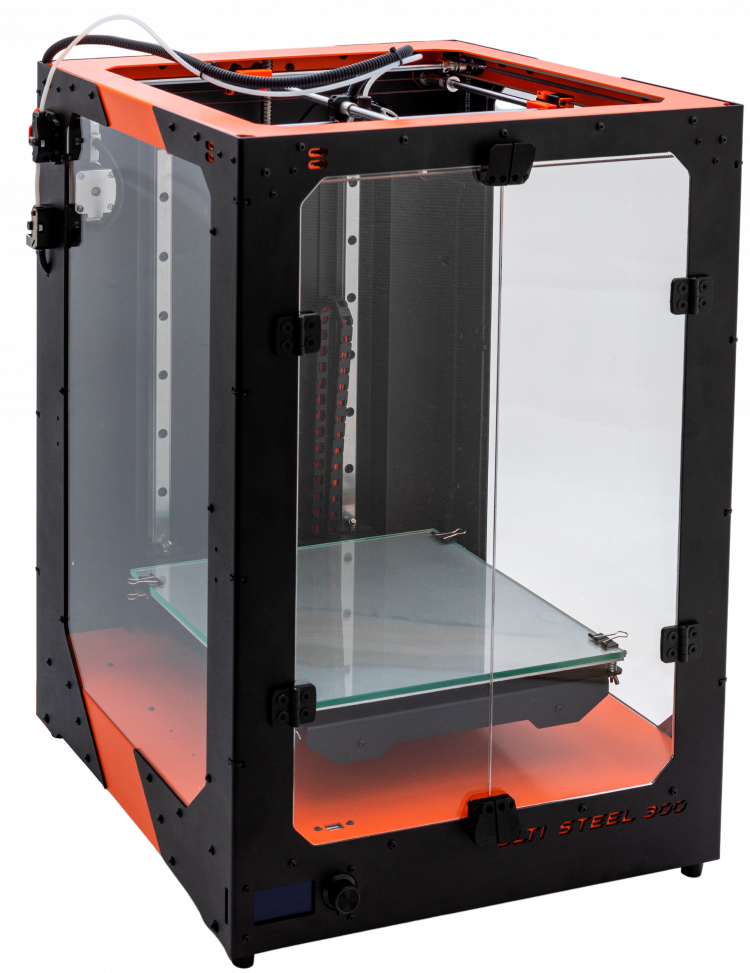

- UlTi Steel 2 – This 3D printer is recommended for those who are looking for a device with advanced functionality, capable of creating durable parts from popular composite materials. It supports a wide range of materials including ABS, PLA, SBS, Hips, Pet-G, PVA, Nylon, Wax, Flex, and optionally ABS GF4, Total GF10, Termax GF10, and other composite materials. The maximum nozzle temperature of the device can reach 290°C, and the maximum table temperature can reach 130°C. The dimensions of the printed area are 200x200x270 mm.

- Creality3D Ender 3 – This is one of the most popular 3D printers due to its relatively low price and workmanship. The printer is ideal for beginners and is often recommended in 3D printing communities. It supports printing with materials such as PLA and SBS, Pet-G, and with some modifications, it can work with ABS and Flex. The maximum temperature of the nozzle is 260°C, and the table – 100°C. The size of the printed area is 220x220x250 mm.

- KingRoon KP3S – Information about this printer is less detailed, but it is also listed among the recommended models. Like other devices, it offers good performance for 3D printing, suitable for both hobbyists and those looking for a printer for more professional use.

Prices for these models can vary greatly depending on the region of sale, supplier, and availability of current updates or promotions. It is recommended to check the current price directly with sellers or on specialized platforms for selling 3D printers.

The use of 3D printing diversifies and opens up new prospects for innovation in various fields. So, the future of this technology promises to bring even more amazing breakthroughs and changes to traditional ways of production and creativity.

Thank you for your attention!