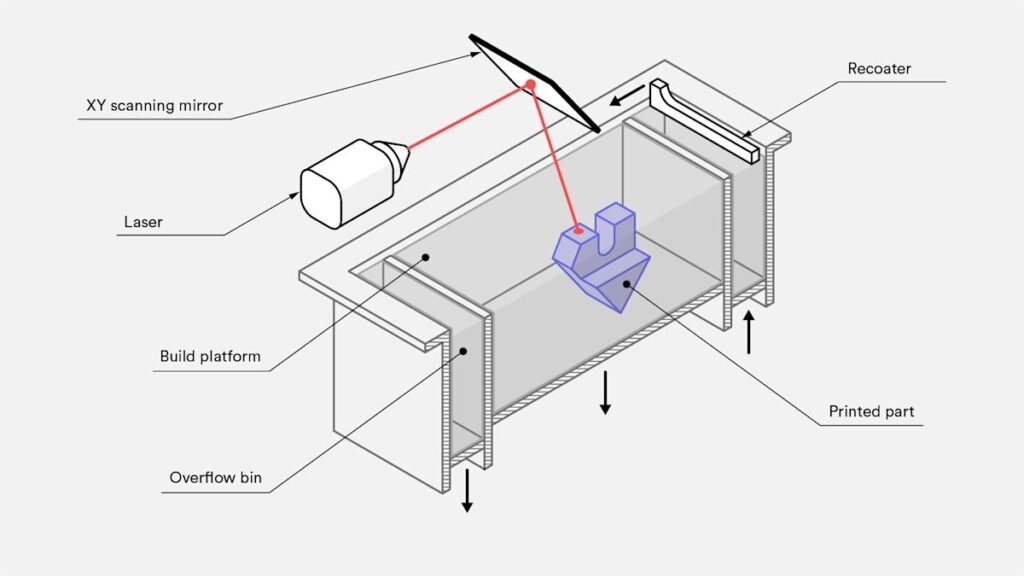

SLS 3D printing, or selective laser sintering, is an advanced additive technology that allows you to create objects by sequentially sintering powder materials with laser radiation. Historically, SLS technology has found application in various industries due to its ability to produce complex geometric parts with high precision and mechanical strength.

How SLS Works

The operating principle of the SLS machine is that a laser sequentially scans the surface of a thin layer of powder, selectively sintering it in accordance with a digital 3D model. After one layer is sintered, the powder bed is lowered and the process is repeated for the next layer until the object is completely formed. This technology is applied to a variety of powder types, including polymers, metals and ceramics, expanding its application from prototyping to final product manufacturing.

One of the key benefits of SLS 3D printing is the ability to create complex and interconnected structures without the need for support structures, significantly reducing material waste and post-printing time. However, despite these advantages, there are also disadvantages, such as a limited choice of colors and high costs for equipment and materials.

Applications

SLS 3D printing is widely used in a variety of industries, from aerospace to medical and automotive, demonstrating its ability to produce functional components, personalized medical implants and complex parts that are difficult or even impossible to produce using traditional methods.

In the automotive industry, for example, SLS 3D printing allows the creation of parts with unique properties, such as lightweight and strong chassis components, custom-designed interior components, and complex cooling and ventilation mechanisms. These parts can be optimized to improve aerodynamic performance, reduce vehicle weight and improve fuel efficiency.

For medicine, SLS 3D printing offers the possibility of creating customized implants and orthopedic devices that precisely match the patient’s anatomical features. This ensures a higher level of comfort and treatment efficiency, for example in orthopedics, dentistry and reconstructive surgery.

As for printer models suitable for these purposes, the following stand out among them: EOS P, 3D Systems sPro, and Sintratec S2. These systems are capable of processing a wide range of materials, from polymers to metals, and provide the high precision and print quality required for the production of both industrial components and medical devices.

The speed of SLS 3D printing is often considered high compared to other additive technologies such as FDM (Fused Deposition Modeling) or SLA (Stereolithography). The main difference is in the method of building the object: SLS printing is capable of processing an entire layer of powder in a single pass of the laser, while FDM and SLA technologies build objects sequentially, adding material line by line or point by point. This means SLS can produce complex and high-volume objects faster, especially when it comes to filling large powder chamber volumes with multiple objects in a single print cycle.

For example, producing a small batch of complex components the size of a cubic centimeter can take several hours on an SLS printer, whereas on an FDM printer it can take significantly longer due to the need to build each layer individually. However, exact speed comparisons will depend on specific printer models, their settings, and the complexity of the items being printed.

Custom Car Parts

SLS 3D printing in automotive opens the door to producing parts that can make even the most boring cars sing and dance, or at least feel a little more special. Imagine being able to print not just regular fasteners or ventilation grilles, but things like:

- Custom door handles that can look like your favorite gadget from a sci-fi movie. Why not make a door handle in the shape of a lightsaber?

- Aerodynamic features like spoilers and body kits can make your car look like it’s ready to fly straight to the moon, not to mention a slight performance boost.

- Custom dashboard panels where every button and lever can be designed to suit your unique style. Who said a control panel can’t look like a spaceship remote control?

- Optimized engine parts, such as lightweight and durable components that can make your car sound like a race car, even if it’s just a family minivan.

- Ventilation and cooling packages that can be so sophisticated and efficient that your car will feel like it’s on holiday in the Mediterranean breeze.

Toys and Collectibles

With SLS 3D printing you can create toys and souvenirs that will make your friends and relatives wonder if you brought them from the future. Here are some ideas:

- Personalized Action Figures: Why not create miniature versions of yourself and your friends as superheroes? With SLS printing you can add any details, whether it’s your favorite T-shirt or that superhero cape you’ve always wanted.

- Create puzzles that will make Einstein scratch his head. Complex 3D puzzles with unique shapes and mechanisms can be an excellent gift for those who like to tinker with their brains.

- Board Games: Imagine a board game where each piece, each board element, or even the dice has a unique style. With SLS 3D printing you can create the board game of your dreams, where even the dragons on the board look ready to fly.

- Models for Collectors: Build a collection of models, from ancient castles to spaceships, with such a level of detail that every little window and hatch has its place.

- Costume Accessories: Need a tiara for a princess costume or a pirate medallion? SLS printing allows you to create accessories that will make your Halloween costume or theme party unique.

- Musical Instruments: How about a miniature guitar that’s almost real? Or flutes with unique designs? Musical instruments printed on a 3D printer can become not only toys, but also real works of art.

Jewelry Design

SLS 3D printing makes it possible to turn the most daring ideas for jewelry and jewelry into reality, adding unique charm and zest to your style. Here are a few options that may inspire you to create something unique:

- Rings with unusual patterns: Why stop at ordinary shapes when you can create a ring in the form of a miniature labyrinth or a secret message in the form of a pattern that is revealed only at a certain angle?

- Pendants with Personal Meaning: Like little time capsules, they can hold 3D prints of your memories, be they miniature versions of places you’ve visited or images of loved ones turned into art pieces.

- Puzzle Earrings: Who said jewelry has to be boring? Imagine earrings that can be put together and taken apart, adding an element of play to your look.

- Modular Design Bracelets: Create a bracelet that can be customized every day by adding or subtracting elements to suit your mood or style. Today it can be an elegant chain, and tomorrow it can be a wild mix of symbols and

- Uniquely shaped hair clips and pins: Why settle for simple accessories when you can create a clip in the shape of your favorite mythical creature or even a miniature sculpture to adorn your hairstyle?

Tools and Gadgets

With SLS 3D printing, you can create tools that are not only functional, but can also become real showpieces in your tool arsenal. Here are some examples:

- Multitools for Every Occasion: Imagine a tool that combines a screwdriver, a bottle opener, a miniature laser sword (well, really, just a small flashlight) and anything else you can think of. SLS printing allows you to create such multitools with a unique design and functionality.

- Custom Tool Handles: Handles for screwdrivers, hammers, or pliers that not only fit perfectly in your hand, but can also have unique patterns, textures, or even your name. Who said tools have to be boring?

- Specialized Jigs and Jigs: Sometimes a specific tool is needed to complete a specific task. SLS 3D printing allows you to create templates, guides or holders for drilling, cutting or soldering that are perfect for your project.

- Modeling and Crafting Tools: Miniature chisels, vices and other tools that can be useful in jewelry making, modeling or fine crafting. These tools can be so detailed and precise that they allow you to work with the smallest details.

- Tools with “intelligence”: By integrating elements of smart electronics into tools, you can get gadgets that not only help you with your work, but can, for example, track usage time, remind you to take a break, or even show the battery charge level.

In the world of SLS 3D printing, there is no limit to your engineering genius and creativity. From creating unique tools that will be an enviable addition to your arsenal, to developing entirely new devices that could revolutionize the way we approach crafts and DIY projects.

SLS 3D Printing in Medicine: Future Innovations

In the medical field, SLS 3D printing opens the door to the creation of not only functional but also highly innovative items that can inspire surprise among patients and delight among healthcare professionals. Here are some examples of what you can create:

- Orthotic devices straight out of science fiction: Braces, corsets, orthoses and dentures that can look like they’re straight out of the future or out of space opera, providing style as well as functionality.

- Custom Surgical Instruments: What if every surgeon had a set of instruments designed specifically for his or her hand, taking into account personal preferences and specific operations? This could improve precision and comfort during complex procedures.

- Educational Models and Simulators: Anatomical models that simulate real-life medical situations with amazing accuracy can not only be a useful tool for training future physicians, but can also contain elements that glow in the dark or change color to show different functions and conditions.

- Rehabilitation and physical therapy products: Rehabilitation devices and accessories that are tailored to the individual patient can be not only effective, but also fun to use, including elements of play or interactivity.

SLS 3D printing allows doctors and patients to not only dream about the future of medicine, but also actively participate in its creation, developing and implementing objects that once seemed possible only in science fiction.

Challenges

While creating all these amazing things with SLS 3D printing, there will undoubtedly be some challenges related to materials. Here are some potential obstacles:

- Cost of materials: Some specialized powders for SLS 3D printing can cost more than your monthly subscription to a streaming service, especially if you plan to print custom implants or exclusive car parts.

- Affordability and Variety: Finding the perfect powder that meets all your color, texture and mechanical properties requirements can sometimes be more difficult than picking the winner of a molecular beauty contest.

- Handling and storage: Some SLS printing powders require special storage conditions, such as protection from moisture or light. It can make you feel like a custodian of ancient relics.

- Post-Processing: Even after printing, your creation may require additional processing such as polishing, dyeing or coating. It can turn your workshop into a miniature laboratory with various chemicals and tools.

- Environmental Considerations: When handling powders and waste materials, it is important to consider their environmental impact. Don’t forget that even as we create the wonders of technology, it is important to take care of our planet.

Costs

There are several models of SLS 3D printers on the market, the cost of which varies depending on their characteristics and capabilities. Here are some examples:

- Sinterit Lisa X: This printer offers print speeds of up to 14 mm/h, allowing most print jobs to be completed within 24 hours. The print area is 130 x 180 x 330 mm, and the printer costs about $23,990.

- Formlabs Fuse 1: This model is the first SLS 3D printer from Formlabs and offers a print speed of 10 mm/s with a layer thickness of 100 microns. The print area size is 165 x 165 x 320 mm. The Formlabs Fuse 1 is noted as a rugged powder printing solution, but may be too expensive for some users.

- Nexa3D QLS 230: This is a more affordable version of the industrial SLS 3D printer, suitable for budget users in industry. The printer is capable of printing parts in 24 hours thanks to a fast sintering process followed by cooling in just 2 hours. The size of the printed area is 230 x 230 x 230 mm.

In general, the cost of SLS 3D printers can range from $10,000 to $20,000 for entry-level, $50,000 to $100,000 for mid-range printers, and can exceed $250,000 for high-end industrial models. It is important to consider that the costs of materials, maintenance and operation are added to the cost of the printer.

Materials

There are many materials available to work with SLS 3D printing technology, each of which has unique properties and is suitable for different applications:

- Polyamides (PA): The most common are PA 12 and PA 11. PA 12 is known for its thermal and mechanical properties as well as chemical resistance. It is used to create functional prototypes and final products, including food products due to its biocompatible options. PA 11 offers higher elasticity and is biodegradable, making it suitable for the automotive industry and the production of protective coatings for water pipes, as well as for the manufacture of bicycle parts and sports shoe soles.

- Thermoplastic Polyurethane (TPU): This material offers high elasticity and strength, ideal for products that require rubber-like flexibility. TPU is widely used in the automotive, aerospace, medical and luxury goods industries to make hoses, bumpers, handles, gaskets, seals and even toys.

- Carbon Fiber Filled Nylon: This composite material combines polyamide powder with carbon fibers to provide an outstanding weight-to-strength ratio and high rigidity. However, products made from this material are anisotropic, which means the properties differ depending on the direction. This material is suitable for the manufacture of parts where thermal properties and high strength are important.

- Glass Filled Nylon: This composite improves the tensile strength and heat resistance of polyamide by adding glass powder. It is used to make functional prototypes, protective cases and sporting goods. Such products are characterized by high resistance to wear and high temperatures.

Each of these materials has unique properties such as strength, elasticity, heat resistance and chemical resistance, making them suitable for a wide range of applications in industries ranging from automotive to medical. When choosing a material for SLS 3D printing, it is important to take into account the specifics of the project and the required characteristics of the finished product.

SLS 3D printing materials, such as PA-12 Nylon powders, typically cost between $150 and $250 per kilogram. These prices are averages and may vary depending on the manufacturer and specific material properties.

SLS 3D printing is like a magic wand in the world of manufacturing: point it at powder and it will turn it into any part, be it something amazing for a spaceship or just a stylish phone case. It can work wonders, turning powder dreams into solid realities, all with virtually no waste! If Harry Potter was into 3D printing, he would definitely choose SLS. Therefore, if you want to feel like a real wizard in the world of technology, SLS 3D printing is your choice.

Thank you for your attention!!!