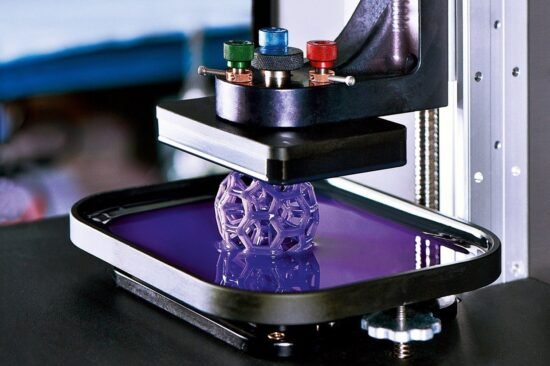

The Rise of Resin 3D Printers

If you’ve been in the 3D printing world for a while, you might have noticed that resin 3D printers are becoming the talk of the town. And why not? When it comes to achieving intricate designs and high-detail 3D printing, these machines are the go-to choice for professionals and hobbyists alike. Whether you’re crafting miniatures that look straight out of a fairy tale or designing precise dental models, resin 3D printing has got your back.

Now, let’s break down the types of resin 3D printing technologies. The most common are SLA (Stereolithography), DLP (Digital Light Processing), and MSLA (Masked Stereolithography). Each of these technologies uses photopolymer resin, which is cured using UV light, allowing for detailed and precise prints. The terminology might sound a bit like a new sci-fi series, but trust me, it’s more about precision than intergalactic wars.

SLA 3D Printing

SLA 3D printing is like the grandparent of resin printing technologies. It uses a laser to cure liquid resin layer by layer. The laser’s precision ensures high-resolution 3D printing, making it ideal for intricate designs. Imagine using a tiny, invisible paintbrush to create a masterpiece—pretty cool, right? SLA printers are often chosen for their ability to produce smooth surfaces, which is why they’re a favorite in industries like dentistry and jewelry.

DLP 3D Printing

DLP 3D printing, on the other hand, uses a digital projector screen to flash a single image of each layer simultaneously. This can speed up the printing process compared to SLA, where the laser has to trace each layer. Think of it as taking a photo versus drawing something by hand. DLP is known for its excellent surface finish and accuracy, making it another favorite for high-detail 3D printing.

MSLA Technology

MSLA technology is like the hip, young sibling of the group. It combines the principles of SLA but uses an LCD screen to mask UV light, hence the name Masked Stereolithography. It’s faster than traditional SLA and often more affordable than DLP. Plus, MSLA printers are gaining popularity in the hobbyist community due to their balance of speed, cost, and quality. It’s like the Goldilocks of resin printing—just right!

Getting Started with Resin 3D Printing

So, you’re excited to dive into the world of resin 3D printing. But where do you start? First, you’ll need to decide which type of resin 3D printer suits your needs. Whether you’re a professional in need of precision 3D printing or a hobbyist looking to create 3D printer miniatures, there’s a resin printer out there for you.

When it comes to choosing the best resin 3D printer, consider factors like resolution, speed, and build volume. A higher resolution means more detail, but it might come at the cost of speed. Larger build volumes allow for bigger prints, but might also mean a bigger footprint in your workshop. It’s a bit like choosing between a cozy apartment and a spacious house—each has its charm.

Resin Printing Tips for Success

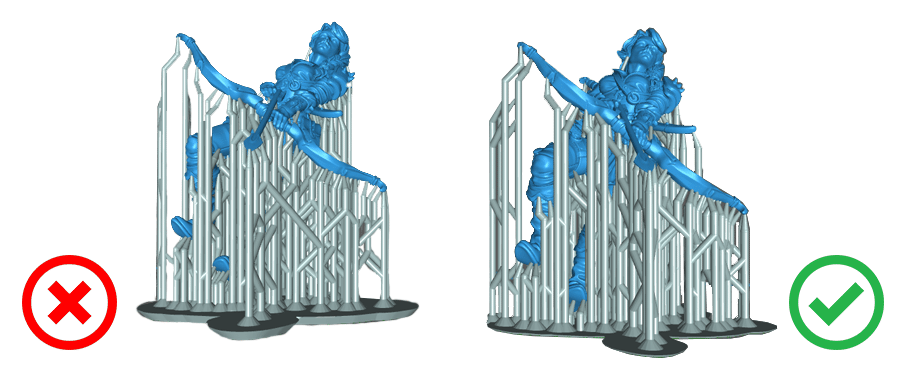

Once you’ve picked your machine, it’s time to roll up your sleeves and get printing. But wait! Resin printing isn’t just a plug-and-play affair. Here are some resin printing tips to ensure your prints come out perfectly:

- Leveling the Build Plate: Always start with a properly leveled build plate. This ensures that your prints stick to the plate and not the bottom of the resin vat. Imagine trying to build a sandcastle on a slope—it’s going to have a bad day!

- Resin Handling: Handle photopolymer resin with care. Use gloves and work in a well-ventilated area. It’s not toxic, but it’s better to be safe than sorry.

- Post-Processing: After printing, your masterpiece isn’t quite ready yet. You’ll need to wash and cure your prints. Washing removes uncured resin, usually done with isopropyl alcohol. Curing further hardens the print using UV light. It’s like giving your print a spa day—wash, rinse, and tan!

Comparing Resin and FDM Printing

At some point, you might wonder how resin printing stacks up against FDM (Fused Deposition Modeling) printing. Resin vs FDM is a classic debate in the 3D printing community. While both have their strengths, they serve different purposes.

Resin printing offers higher resolution and smoother surfaces, making it ideal for detailed models and intricate designs. FDM, on the other hand, is often more affordable and versatile when it comes to materials. It’s perfect for larger, less detailed projects. It’s like comparing a fine brush to a broad stroke—each has its own flair.

Liquid Resin Printing vs. FDM

If you’re printing miniatures or models where detail is paramount, liquid resin printing is the way to go. The liquid resin offers a level of precision that FDM just can’t match. But if you’re building something like a functional prototype or a larger object, FDM might be your best bet. Plus, FDM printers are generally less messy, and who doesn’t love a tidy workspace?

Resin Printing for Various Industries

Resin 3D printing isn’t just for hobbyists tinkering in their garages. It’s also a game-changer for many industries. Dental 3D printing is one area where resin printers shine. Dental models and surgical guides require precision, and resin printers deliver with flying colors—or should I say, with perfect shades of white?

Jewelry 3D printing is another field where resin printers are a hit. The ability to create intricate designs with fine details is a jeweler’s dream. It’s like having a tiny Michelangelo sculpting your designs.

Resin Printer Maintenance

Now, let’s not forget about resin printer maintenance. Just like any piece of technology, your resin printer needs a bit of TLC to keep running smoothly. Regularly clean the resin vat and build plate, and check for any wear and tear. Keep the LCD screen clean and free of cured resin spots. Think of it as a regular health check-up, but for your printer.

The Future of High-Resolution 3D Printing

As technology advances, we can expect even more improvements in high-resolution 3D printing. Newer, faster, and more efficient resin printers are constantly being developed. Who knows, maybe one day we’ll be printing entire houses with resin! Okay, maybe that’s a stretch, but the possibilities are endless.

In the meantime, whether you’re a professional or a hobbyist, resin 3D printers offer a world of creative possibilities. From high-detail miniatures to professional-grade dental models, the precision and quality of resin printing are hard to beat. So go ahead, unleash your creativity, and let your resin printer bring your designs to life. And remember, in the world of 3D printing, the only limit is your imagination—oh, and maybe your workbench space!