So, you’ve stumbled across the term “SLS 3D Printing” and you’re thinking, “Great, another acronym to remember. Is this like the VHS of the 21st century?” Well, in a way, yes. But trust me, SLS isn’t here to ruin your favorite movies; it’s here to revolutionize the way we make stuff. And who doesn’t love a good revolution, especially when it doesn’t involve pitchforks?

What on Earth is SLS 3D Printing?

SLS stands for Selective Laser Sintering, a super cool technology that lets us print, not just in two dimensions like paper, but in three dimensions. Imagine printing a cup, a gear, or even a tiny sculpture of your favorite cartoon character. It’s like having a mini factory at your desk, minus the smoke and industrial noise. The process uses a laser to sinter powdered material, basically zapping it into a solid structure. It’s a bit like playing with a very precise, very expensive ray gun. Pew pew!

How Does It Work?

Okay, let’s break it down like a 90s dance move:

1. The Powder Bed

SLS starts with a bed of powder. This isn’t your grandma’s flour for cookies; it’s a fine layer of material like nylon, glass, or even metal. The powder is spread across a platform, waiting for its time to shine.

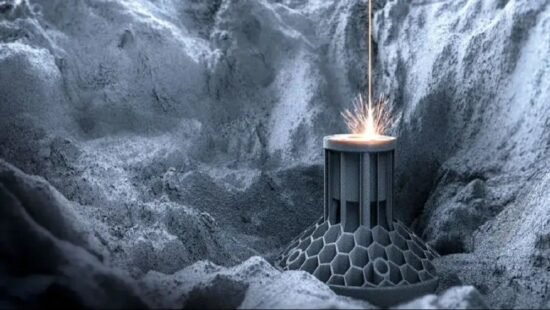

2. The Laser Show

Here comes the laser, which is like the hero of this story. The laser scans the surface of the powder bed, heating it just enough to make it stick together in a process called sintering. It’s like when you leave marshmallows in the sun and they get all gooey but in a good way.

3. Rinse and Repeat

Once one layer is sintered, the platform drops slightly, and a new layer of powder is spread over the top. The laser does its thing again, bonding the new layer to the one below it. This process repeats over and over, like a really productive Groundhog Day, until the object is complete.

4. Cool Down and Clean Up

After printing, the object needs to cool down. You can’t rush these things, just like you can’t rush a good soufflé. Once cooled, the object is excavated from the surrounding powder, a bit like an archaeological dig but with fewer dinosaurs.

Why SLS 3D Printing is a Game Changer

We live in a world where we want things faster, cheaper, and better. SLS 3D printing delivers on all three fronts, and here’s why:

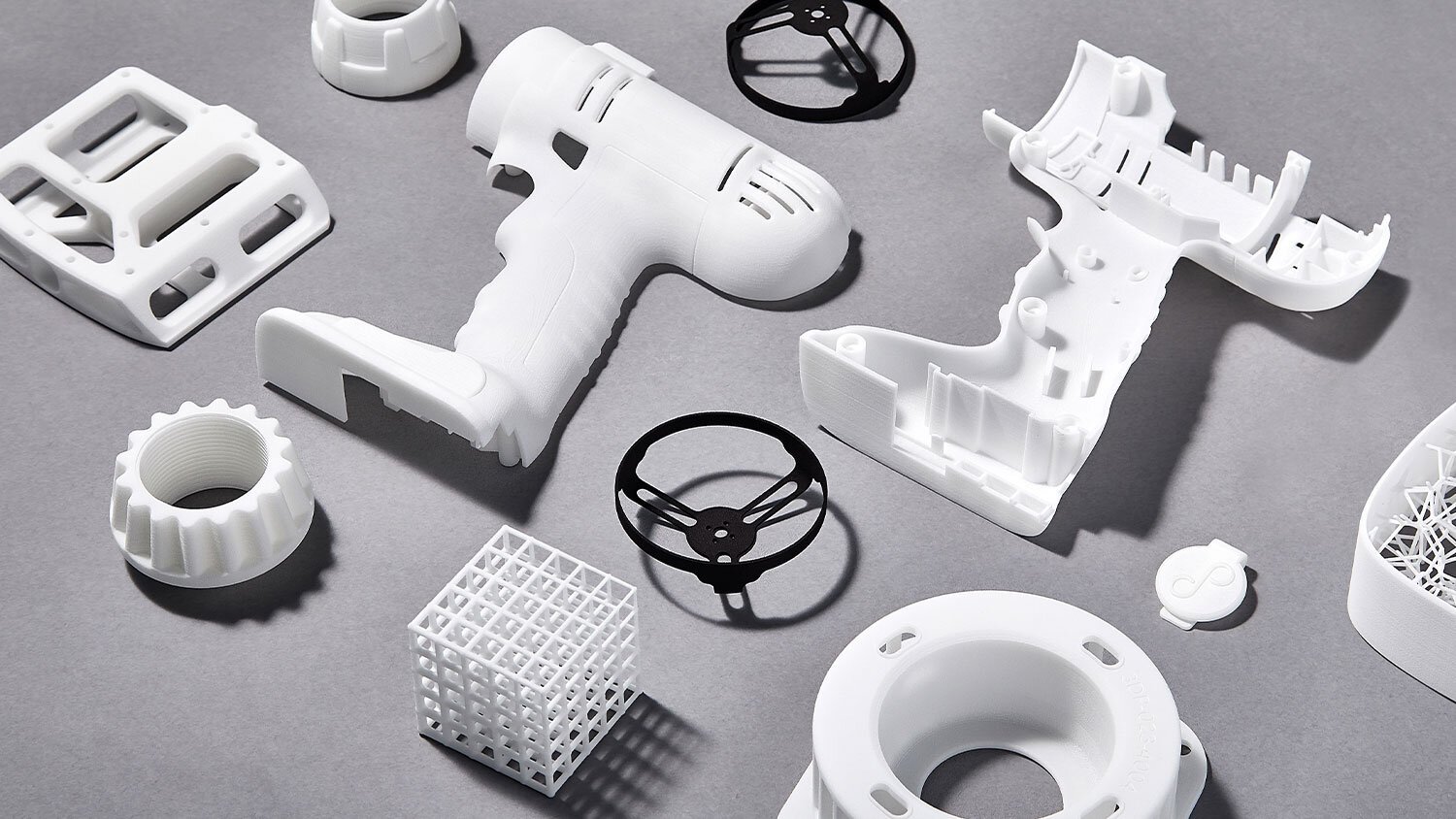

1. Complexity at No Extra Cost

Traditional manufacturing methods often charge you extra for complex designs. It’s like ordering a pizza with extra toppings. But with SLS, complexity is free! You could print a model with intricate lattice structures or interlocking parts, and it won’t cost a penny more than a simple block. It’s like getting those extra guac without the extra charge.

2. Less Waste, More Love for the Planet

In traditional manufacturing, you start with a block of material and cut away the excess, kind of like sculpting a statue. It’s effective but wasteful. With SLS, you use just the material you need. The unsintered powder can be reused, which is great news for your wallet and Mother Earth. It’s like recycling but ten times cooler.

3. Speedy Gonzales Production

Need a prototype yesterday? SLS can help. It’s among the fastest methods for creating prototypes and functional parts. No more waiting weeks for a part to come from a factory halfway around the world. Print it overnight and have it ready for your morning coffee.

4. Material Variety

SLS isn’t picky. It can work with a wide range of materials, including plastics, metals, and ceramics. Want to print a part in nylon and then switch to metal for a different project? No problem. It’s like having a Swiss Army knife in the form of a printer.

The Theoretical Side of Things

For those who like to dig a little deeper, SLS operates on some pretty fascinating principles of physics and materials science. The key concept here is sintering. When the laser hits the powder, it doesn’t melt it entirely. Instead, it raises the temperature to just below the melting point, causing the particles to fuse together. It’s like a dance party where everyone’s getting close but not too close. This partial melting creates a solid structure while maintaining the material’s integrity.

Another interesting aspect is the powder bed itself. It acts as a support for the object being printed. This means you can print complex geometries without needing additional supports, which is a big win over other 3D printing methods that often require scaffolding. It’s like building a sandcastle where the sand holds up its own towers.

Applications of SLS 3D Printing

SLS isn’t just a science fair project; it’s being used in some pretty serious industries. Here’s a quick list to give you an idea:

- Aerospace: Lightweight parts with complex geometries are a dream for aircraft manufacturers.

- Automotive: Custom parts for cars, from prototypes to end-use parts.

- Healthcare: Customized implants and medical devices that fit patients perfectly.

- Fashion: Innovative designs that are impossible with traditional methods.

- Consumer Goods: From eyewear to furniture, SLS is making waves.

Challenges and Considerations

Alright, it’s not all rainbows and unicorns. SLS does have its challenges. For one, the machines themselves can be quite expensive. It’s like buying a fancy coffee machine; once you have it, though, you wonder how you ever lived without it. Also, post-processing can be a bit of a chore, as the parts need to be cleaned and sometimes finished to get that showroom shine.

Another consideration is the learning curve. SLS isn’t as straightforward as hitting “print” on your home office printer. It requires some technical know-how and understanding of materials. But hey, learning new things keeps the brain young, right?

The Future of SLS 3D Printing

While I promised not to delve into the mystical future, it’s hard not to get excited about what’s on the horizon for SLS. As the technology advances, we’re likely to see even faster print times, more materials to choose from, and further reductions in cost. It’s like being on the cusp of a new era, where the only limit is our imagination, and maybe our budget.

In the end, SLS 3D printing is not just a game changer; it’s a life changer. Whether you’re an engineer, a designer, or just someone who loves gadgets, this technology is paving the way for a world where ideas become reality at the push of a button. And if that’s not exciting, I don’t know what is. So, next time you hear SLS, think of it as the VHS of manufacturing, but way cooler and definitely not obsolete.