Imagine having a twin who doesn’t steal your clothes or fight for the last slice of pizza. Instead, this twin exists in a digital realm, mirroring your every move, predicting your next steps, and sometimes even offering better solutions. Welcome to the world of digital twins—the non-annoying sibling of the future.

What Exactly Are Digital Twins?

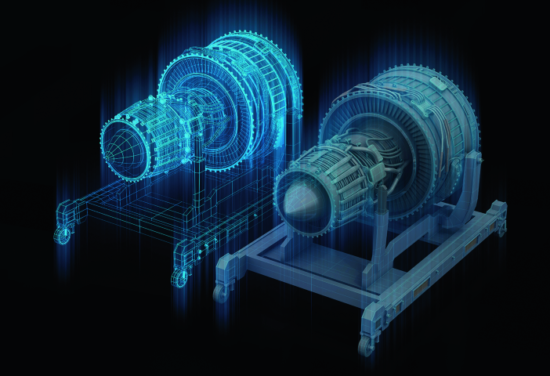

The concept of digital twins emerged from NASA’s need to improve the simulation of their physical systems. These virtual replicas are created to mirror physical entities, whether they’re buildings, jet engines, or even entire cities. Think of it as a super-intelligent hologram that doesn’t just look like the original but behaves like it too.

In simple human terms, digital twins are like those video game avatars that look and act just like you—except they’re used for more than just jumping over barrels or collecting coins. They allow us to test, tweak, and optimize without touching the real thing, saving time, money, and more importantly, those awkward moments when you have to admit you broke it.

How It Works?

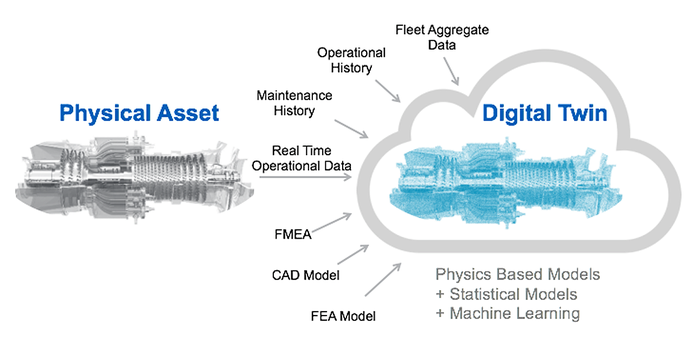

Digital twins work by creating a virtual replica of a physical object, system, or process. Using sensors and real-time data, they gather information from the physical counterpart, such as temperature, movement, or pressure, and transfer this data into the digital model. This virtual model is continuously updated, allowing for real-time monitoring, analysis, and simulation. By simulating various scenarios, digital twins help predict outcomes, optimize performance, and even identify potential issues before they arise. They are used in industries like manufacturing, healthcare, and urban planning to improve efficiency, reduce costs, and drive innovation.

Applications of Digital Twins

Digital twins are not just for the tech-savvy or the science fiction fans among us. They have practical applications across a variety of fields:

- Healthcare: Imagine doctors having a digital replica of your body. They could simulate surgeries, test treatments, and predict health issues without making a single incision. It’s like having a personal healthcare assistant that doesn’t judge your eating habits.

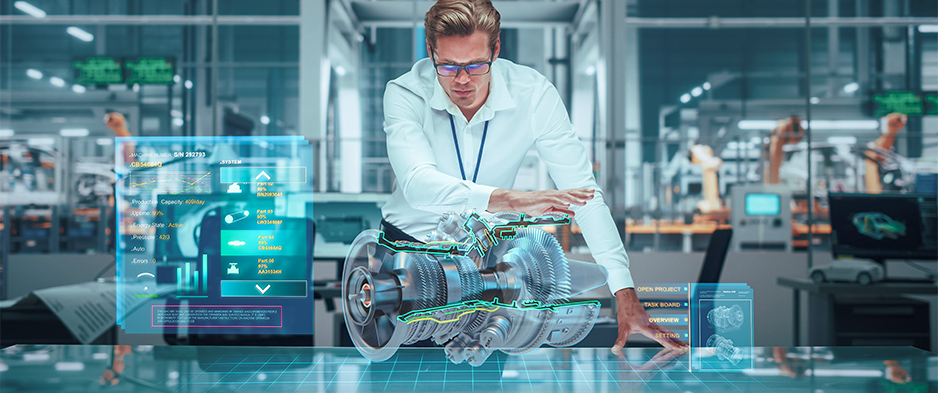

- Manufacturing: Factories can use digital twins to streamline production processes, detect faults, and improve product quality. It’s the perfect way to keep those assembly lines moving smoothly, without the need for a real-life Mr. Fix-It on call.

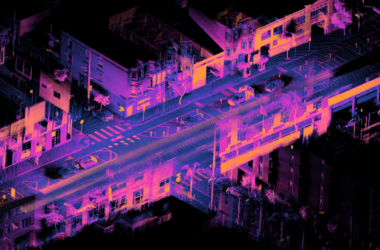

- Urban Planning: Cities are now using digital twins to visualize urban developments, manage resources, and prepare for emergencies. It’s like SimCity but with less pixelated graphics and more real-world impact.

- Automotive: Car manufacturers can simulate vehicle performance under various conditions. This means fewer test crashes and more time for engineers to daydream about flying cars.

The Benefits of Embracing Digital Twins

The advantages of digital twins are as numerous as the times you’ve forgotten your Wi-Fi password. Here are a few reasons why they’re making waves:

- Cost Efficiency: By predicting failures and optimizing processes, digital twins can significantly reduce maintenance and operational costs.

- Improved Productivity: With accurate simulations, businesses can streamline operations and enhance productivity. It’s like having a personal trainer for your industrial processes.

- Enhanced Innovation: Digital twins provide a sandbox for testing new ideas, leading to faster and safer innovation cycles.

- Risk Reduction: By foreseeing potential issues, digital twins help in mitigating risks, ensuring smoother operations.

Challenges on the Horizon

As promising as digital twins sound, they’re not without their quirks. For one, they require a constant stream of data, and with great data comes great responsibility—or at least, great data management. Keeping all that information secure and up-to-date can be a Herculean task, especially when you consider the potential for cyber threats. It’s like trying to keep a pet goldfish alive while juggling flaming torches.

There’s also the challenge of integration. Digital twins need to be seamlessly integrated into existing systems, and this can often resemble trying to fit a square peg into a round hole, but with more wires and fewer laughs.

What’s Next for Digital Twins?

Despite these challenges, the future of digital twins is as bright as a techie’s smartphone screen at midnight. As technology evolves, so too will our ability to create more accurate and sophisticated digital twins. This will open new possibilities, from personalized consumer experiences to smarter, more sustainable cities.

For now, digital twins remain an exciting frontier in the tech world, offering a glimpse into a future where we can interact with our world like never before. So, the next time you find yourself wishing for a twin to do your chores or take your place in a Zoom meeting, remember that the digital version might just be around the corner, ready to revolutionize more than just your to-do list.

Until then, let’s appreciate our digital twins for what they truly are—the future of virtual replicas, minus the sibling rivalry!