Decoding 3D Scanning in the Realm of Reverse Engineering

In the bustling world of design and manufacturing, 3D scanning is steadily carving out a niche for itself in the arena of reverse engineering. Imagine being able to take a tangible object, capture its exact proportions, intricate details, and unique features, then re-create it digitally. Sounds pretty neat, don’t you think? Well, that’s exactly what 3D scanning can do, thereby making the life of an engineer a less complicated and a tad more exciting. But what makes this technology tick, and where do we see it flexing its digital muscles? Fasten your virtual seatbelts, and let’s embark on a quick digital exploration.

Peeling Back the Layers of 3D Scanning in Reverse Engineering

Before we unravel the lasting impression 3D scanning is leaving on reverse engineering, let’s immerse ourselves into the core techniques that give this technology its superpowers.

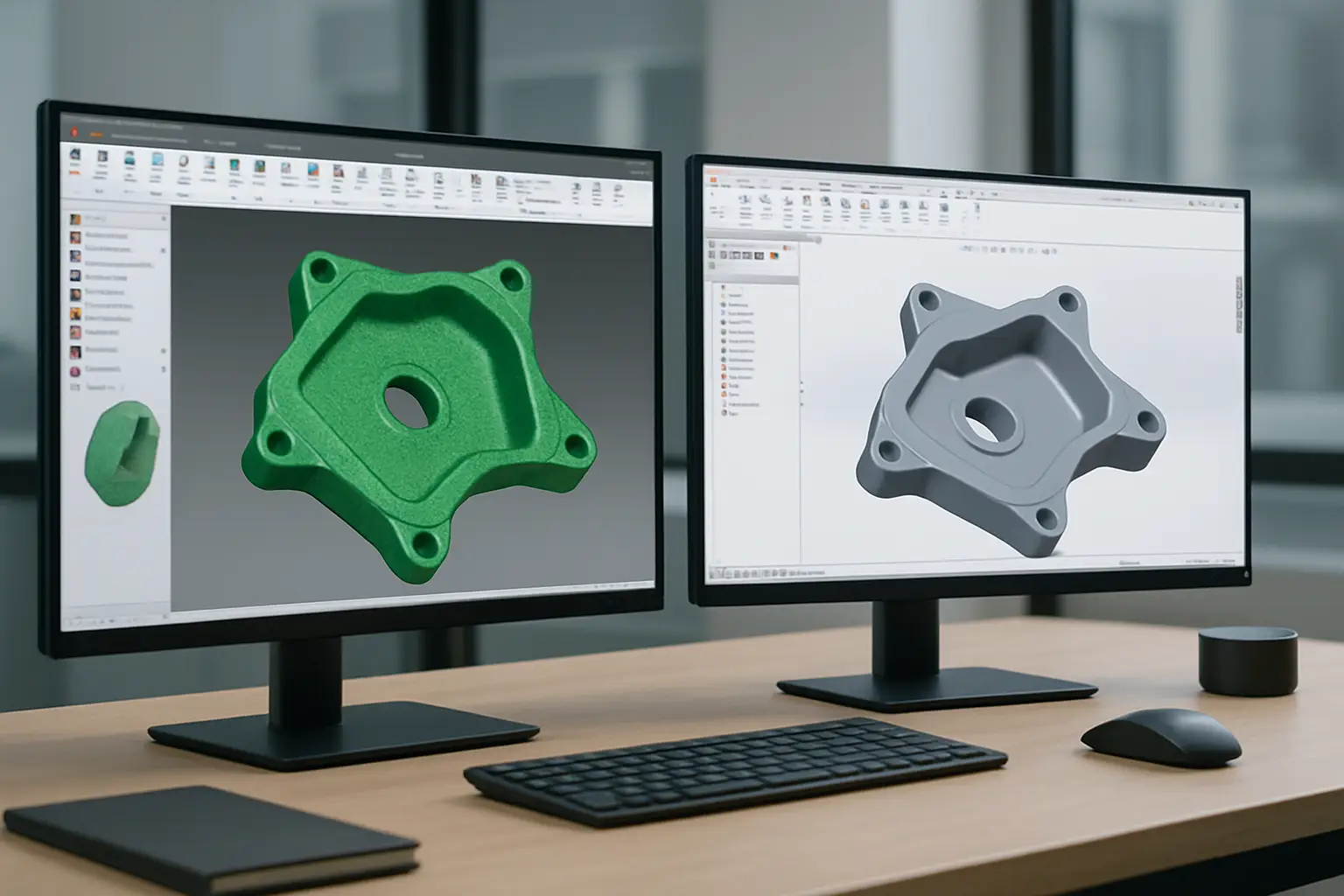

From Reality to Virtuality: The Digital Model Transformation

Reverse engineering thrives on the capacity to create accurate digital models out of physical objects. In this domain, 3D scanning is a bit like the fairy godmother of Cinderella. Just as she transformed a pumpkin into a grand carriage, 3D scanning converts an everyday object into a detailed, perfect, digital replica. How, you ask? Let’s dissect the process:

-

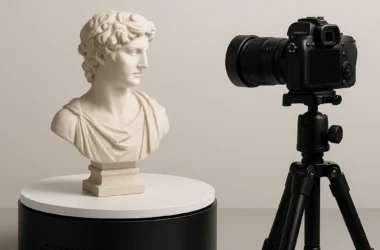

The Digital Birth: A specialized 3D scanner shines lasers or structured light on the object in focus, captures the reflected signals, and gives birth to a detailed point cloud—a digital map of the object’s features and contours. I’ve always thought of it as the universe’s version of a 3D dot-to-dot.

-

The Clean-Up Stage: The raw data, sometimes a little rough around the edges, is then processed through software that grooms it into a polished and practical 3D model primed for tinkering within CAD programs.

-

Sprucing up the Model: Having nurtured the digital model, designers then refine it, like a sculptor smoothening a statue, removing design flaws, prepping it for production, or enhancing its functionality, as needed.

The Magic of Replica Creation

One major superpower 3D scanning flaunts is its capability to clone parts. And trust me, there’s nothing creepy about this cloning—it’s seriously handy when manufacturers need to replace outdated components or create custom parts. Just like how you’d make a smoothie, 3D scanning tosses in two core ingredients:

- Precise part cloning, which strengthens compatibility and product lifecycle management.

- Tailoring opportunities, empowering engineers to twist and tweak the design based on results and feedback without having to start from scratch.

The Pros and Cons of Wielding the 3D Scanning Wand

With an understanding of the behind-the-scenes operation, let’s weigh the pros and cons of using 3D scanning in reverse engineering.

| Strengths | Weaknesses |

|---|---|

| Exceptional detail capture | Potential blunders if not calibrated correctly |

| Serious time savings VS conventional methods | Specialist personnel needed for data processing and modeling |

| Seamless prototype and design tweaks | Initial costs for equipment and software |

| Bounty of customization scopes | Certain materials resist precise scanning |

Diving into the Digital Toolbox: 3D Scanning Software

Software Titans

Diverse 3D scanning technologies and software are available to make engineers’ and designers’ lives easier. Here are the key players you might like to know:

- Geomagic Design X: A digital maestro, blending 3D scanning with CAD design to facilitate the creation of high-fidelity models.

- SolidWorks: A popular companion for scanning devices, allowing users to mold usable models straight from scan data, simplifying design modifications and versions.

- MeshLab: An open-source knight in digital armor that tidies up and processes 3D mesh data, ensuring the scanned data is all set for modeling.

The Footprint of 3D Scanning in the Real World

Peeking out from the CAD workspace, we find 3D scanning leaving an indelible mark across an array of industries, fueling reverse engineering efforts. Let’s have a glance at some compelling examples:

-

Automotive Industry: Car manufacturers, like Ford, are using 3D scanning to create spare parts clones for restoring vintage cars. It’s a bit like having a digital clone of your favorite old jeans, ready to replace the worn-out original.

-

Aerospace Realm: Big names like Boeing lean on 3D scanning during aircraft part inspections to guarantee they meet safety regulations, accelerating the approvals and modification processes.

-

Consumer Electronics: Tech giant Apple often wields 3D scanning to simulate new gadgets, allowing brisk prototyping and testing before jumping into final production.

Each example serves as a testament to how 3D scanning elevates precision, bolsters productivity, and beautifully streamlines processes during reverse engineering.

For more insights on how 3D scanning is leaving an imprint on other sectors like fashion and art, consider checking out these articles on 3D Printing and Fashion and The Art of 3D Printing.

Wrapping It Up

In the grand panorama of reverse engineering, 3D scanning stands as a cornerstone, offering a smorgasbord of benefits expediting the creation and duplication of objects. Its prowess in delivering precision, slashing costs, and sparking innovation renders it indispensable for industries vying for the competitive edge. As technology races ahead, embracing 3D scanning within reverse engineering workflows will only ascend in importance.

Time to Reflect

If you’re part of an industry that values precision and efficiency (which I suspect you are), peek over the tech fence to see whether 3D scanning could elevate your capabilities. This technology might just be the key unlocking your next creative milestone. But hey, don’t take my word for it, why not experience it for yourself?

A Swift Q&A Swing

1. Could you outline the main steps in 3D scanning for reverse engineering?

Certainly! It’s a three-step cha-cha: data capture, data processing, and model refinement using CAD software.

2. What makes 3D scanning score over traditional methods?

Well, 3D scanning is like a digital Superman—delivering higher accuracy at lightning speed, saving heaps of time, and reducing material waste. Oh, and it doesn’t need a cape!

3. Could you highlight some popular software tools used for processing 3D scans?

Sure! Popular ones include Geomagic Design X, SolidWorks, and MeshLab, among others. Each offers unique capabilities, like a superhero’s individual flair.

4. How does 3D scanning amp up accuracy and efficiency during reverse engineering?

By capturing exact geometries within moments, 3D scanning enables swift iterations and modifications while ensuring a snug fit with existing designs.

5. Any industries where 3D scanning shines particularly bright in reverse engineering?

Absolutely! 3D scanning finds a warm welcome in automotive, aerospace, and consumer electronics industries, to name but a few.

Dive into the digital world of 3D scanning in your projects, and you might just discover a new, dynamic way to approach reverse engineering!