What is SLS 3D Printing?

If you’re venturing into the realm of 3D printing, you’ve probably come across the term SLS, or Selective Laser Sintering. But what does that really mean? Simply put, SLS is a 3D printing technology that uses a powerful laser to fuse powdered materials into solid structures. It’s like sculpting with lasers, except you don’t need an academic background to understand the basics!

A Brief History of SLS Technology

SLS has its roots in the 1980s, initially developed by a team led by Dr. Carl Deckard at the University of Texas. The idea was revolutionary: the ability to create complex geometric shapes that were previously impossible with traditional manufacturing methods. Fast forward to today, and SLS is widely used across various industries for prototyping and small-batch production. It has evolved significantly, integrating advances in laser technology and material science. It’s a classic case of “shooting for the stars” and ending up with something that fundamentally changes the game.

How Does SLS 3D Printing Work?

Behind the sleek outer shell of an SLS printer lies a fascinating process that combines laser engineering with smart technology. Let’s break it down further.

Laser Sintering Process

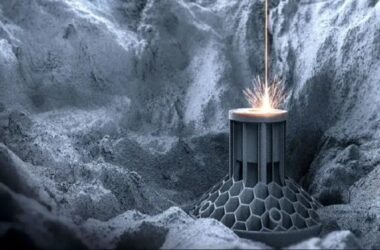

The core of SLS technology involves a high-powered laser that selectively sinters powdered material — typically nylon or other polymer powders — layer by layer. The process starts with a bed of powder, and the laser scans and fuses the particles according to the 3D model you’ve provided. Once a layer is complete, the machine lowers the build platform, and a new layer of powder is rolled over the previous one. This continues until the entire object is built.

Imagine building a sandcastle, but instead of using water and sand, you’re using laser beams and powder!

Materials Used in SLS

While SLS primarily uses thermoplastic polymers, the range of materials has expanded significantly. Here are some of the most common ones:

- Nylon (PA): Known for its strength and flexibility, making it ideal for various applications.

- Polycarbonate: Offers excellent impact resistance, suitable for tougher prototypes.

- Metal powders: While more niche, metal SLS (like titanium or aluminum) opens the door to lightweight, durable metal components.

- Elastomers: These provide flexibility for applications requiring bendable parts.

Choosing the right material is crucial, as it directly impacts the performance of the final product.

Equipment and Machinery

An SLS printer typically includes a laser source, a powder feed system, and a build chamber. Brands like EOS, 3D Systems, and Formlabs offer industrial-grade SLS machines that vary in capabilities and price. On the consumer side, there are emerging brands offering more accessible versions that can fit into smaller workshops — perfect for aspiring makers looking to explore SLS.

Applications of SLS 3D Printing

The versatility of SLS technology means it finds applications in a variety of sectors. Let’s explore a few.

Industries Utilizing SLS

- Aerospace: Lightweight, complex parts can be manufactured to meet exacting standards. Every gram counts when it comes to flight!

- Automotive: Prototyping of parts and fixtures, as well as small-run production, allows for rapid iteration and cost efficiency.

- Medical: Custom implants and prosthetics that are tailored to individual patients can be made quickly and with precision.

- Consumer Products: From footwear to gadgets, SLS is used to create unique products that resonate with consumers.

Case Studies or Examples

One fascinating example comes from the automotive industry: companies like BMW are using SLS to produce lightweight components for their vehicles, significantly reducing weight and improving fuel efficiency. Another great example is in the medical realm, where SLS is used to create customized dental parts — tailored to fit perfectly, ensuring comfort and functionality.

Advantages and Disadvantages of SLS 3D Printing

Let’s take a moment to weigh the pros and cons of SLS technology before diving deeper.

Pros and Cons

Pros:

- Complex Geometry: SLS can create intricate designs that would be impossible with other methods.

- Material Efficiency: Only the material that is sintered is used, minimizing waste.

- Strong Parts: The resulting objects are durable and suitable for functional applications.

- No Support Structures Required: The unused powder supports the part, reducing post-processing work.

Cons:

- Cost: SLS printers tend to be expensive, making them less accessible for hobbyists.

- Surface Finish: Parts may require post-processing to achieve a smooth finish.

- Speed: The SLS process can be slower than some alternatives, especially for larger or more complex prints.

Specifications of SLS 3D Printers

When considering an investment in SLS technology, it’s vital to understand the specifications of the printers available.

Print Volume and Precision

SLS printers come in various sizes, but typical print volumes range from a few hundred centimeters to over a meter. High precision is one of the selling points of SLS, with layer resolutions generally falling between 0.1 mm and 0.15 mm, allowing for that intricate detailing many industries crave.

Material Properties

When it comes to material properties, SLS is known for producing parts that exhibit excellent tensile strength and toughness. The flexibility of materials like nylon allows for the creation of both sturdy and functional components, often used in real-world applications.

Future of SLS 3D Printing

With technology evolving at breakneck speed, where is SLS 3D printing headed? Predictions include:

- Material Innovation: As new powder materials are developed, the ability to create even more innovative designs will expand.

- Greater Accessibility: As prices drop, we may see more entry-level SLS printers hitting the market, making this technology available to smaller businesses and DIY enthusiasts.

- Integration with Other Technologies: The future might see SLS merging with other printing technologies, like multi-material printing or hybrid systems.

As companies continue to explore new applications, one thing is clear: SLS is here to stay, and it’s poised for significant growth.

FAQ

How does SLS 3D printing differ from other 3D printing technologies?

SLS uses a laser to fuse powdered material, whereas technologies like FDM use filament. This means SLS can produce more complex geometries without support structures.

What are the typical materials used in SLS?

Nylon is the most common, but other materials include polycarbonate, metal powders, and elastomers.

What industries benefit most from SLS 3D printing?

Industries like aerospace, automotive, medical, and consumer products are among the biggest beneficiaries.

Are there any safety concerns with SLS 3D printing?

As with any 3D printing technology, safety precautions should be followed, especially concerning laser operations and powder handling.

How cost-effective is SLS compared to other technologies?

While SLS can be more expensive initially, the efficiency and material properties often justify the investment for professional applications.