Hello dear readers! If you have a 3D printer, then you probably know that this device requires not only attention, but also regular maintenance. Like any other gadget, a 3D printer needs love and care to delight you with its creations. Imagine a 3D printer as a pet – it needs to be fed, walked (or at least ventilated) and, of course, cleaned! In this article, we will tell you how to properly care for your 3D printer so that it serves you faithfully for many years. Ready? Then let’s go!

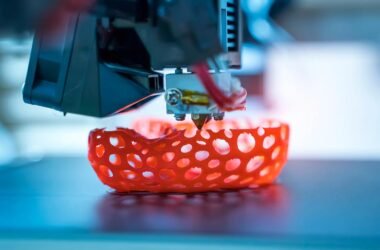

Cleaning the extruder

The extruder is the heart of the 3D printer, responsible for feeding and melting the plastic. Without regular extruder cleaning, clogs may occur, resulting in poor print quality or even machine failure.

To tell if your 3D printer’s extruder needs cleaning, look for the following signs:

- Filament Feed Problems: If the plastic filament does not feed evenly or stops feeding at all, this may indicate a clogged extruder.

- Reduced print quality: Uneven layers, gaps, or distortions in printed models are often caused by a clogged extruder nozzle.

- Unusual sounds: If you hear clicking or popping noises while printing, this may indicate that the extruder is trying to push filament through a clogged nozzle.

- Extruder overheating: A clog can cause overheating as the plastic cannot flow freely through the nozzle.

- Visible Contaminants: If you see carbon deposits or plastic residue on the extruder nozzle, this is a clear sign that it needs cleaning.

- Odor: An unusual odor coming from the extruder during operation may indicate contaminants have accumulated and require cleaning.

To clean the extruder, follow these steps:

- Unplug the printer.

- Preheat the extruder to operating temperature.

- Remove the filament from the extruder.

- Use a special needle or wire to clean the nozzle.

- Wash the nozzle with special solutions to remove plastic residues.

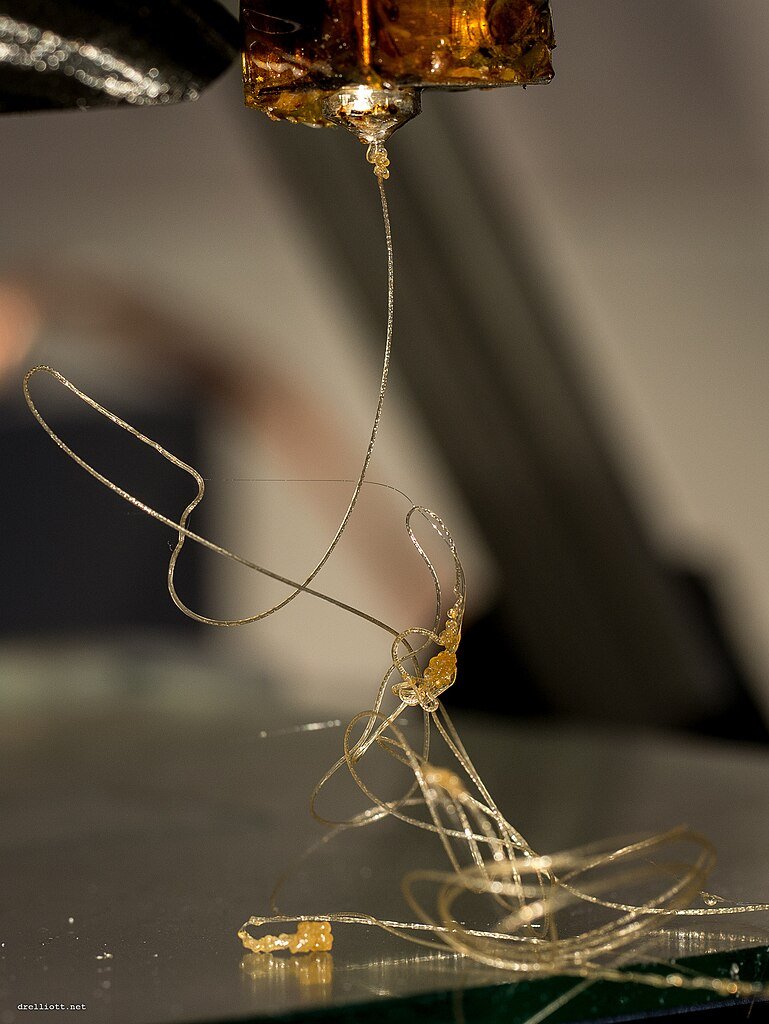

Needles

To clean a 3D printer’s extruder, special needles are used, which can be purchased from various places. Here are some recommendations on where and what kind of needles you can buy.

Where can I buy

- Online stores:

- Amazon: On Amazon you can find sets of needles in various sizes specifically designed for cleaning 3D printer nozzles.

- eBay: You can also find many offers on eBay from various sellers.

- Aliexpress: You can find cheaper options here, but be aware that delivery may take longer.

- Specialized 3D printing stores:

- Many stores that specialize in selling 3D printers and supplies offer extruder cleaning needles.

- Tech and hobby stores:

- Some hobby and modeling stores also carry these tools.

What needles to buy

- Needle size:

- Choose needles that match the nozzle diameter of your 3D printer. The most common sizes are 0.2 mm, 0.3 mm, 0.4 mm and 0.5 mm. Make sure your kit contains the correct size needles.

- Needle material:

- Stainless steel needles are the most popular and durable.

- Needle sets:

- It is recommended to buy sets that contain several needles of different sizes. This will allow you to choose the most suitable cleaning needle.

Product examples

- NIGRIN Needles for cleaning 3D printer nozzles: Set of 10 needles with a diameter of 0.4 mm made of stainless steel.

- Sovol 3D Printer Nozzle Cleaning Kit: Set containing 10 needles of various sizes (0.2 mm, 0.3 mm, 0.4 mm and 0.5 mm).

- Aokin 3D Printer Nozzle Cleaning Tool Kit: Set of 13 needles with different diameters, as well as tweezers for ease of use.

Tips for use

- Always warm up the extruder to operating temperature before cleaning to soften the plastic inside the nozzle and make it easier to remove.

- Be careful when using needles to avoid damaging the nozzle.

- Flushing the nozzle after cleaning with a needle!

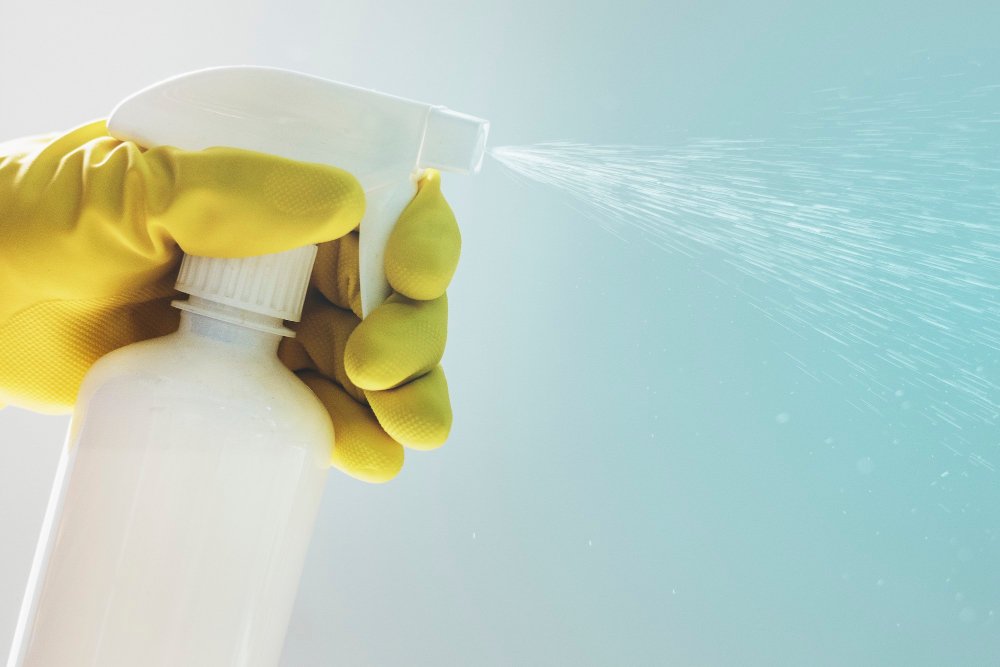

Cleaning liquids

There are several types of liquids you can use to clean your 3D printer extruder nozzle. Here are the main options:

Isopropyl alcohol (IPA)

- Description: Isopropyl alcohol is the most common and affordable liquid for cleaning nozzles and other parts of a 3D printer.

- Benefits: Effectively removes plastic residues, grease and other contaminants. Evaporates quickly and leaves no residue.

- Where to buy: Pharmacies, hardware stores, online stores.

Acetone

- Description: Acetone can be used to clean nozzles, especially if you are printing with ABS plastic.

- Benefits: Dissolves ABS plastic, making it easy to remove blockages and material residues.

- Limitations: Acetone is not suitable for cleaning nozzles if you are using PLA or other plastics that do not dissolve in acetone. May be hazardous if inhaled and in contact with skin, so use in a well-ventilated area and with precautions.

- Where to buy: Hardware stores, online stores.

Special cleaning solutions for 3D printers

- Description: There are special solutions on the market designed for cleaning the extruder and nozzles of 3D printers.

- Benefits: These solutions are safe to use on most types of plastics and are usually more effective than household chemicals.

Clean the print platform

A clean platform is the key to successful adhesion and print quality. Contamination on the platform may cause the model to peel off during printing. To clean the platform, follow these steps: Remove any remaining plastic from the surface.

- Wipe the platform with alcohol solutions to remove grease and dirt.

- Check the condition of the platform covering (BuildTak, glass, etc.) and replace it if necessary.

Removing plastic residue from the surface of the 3D printer platform is important to maintain print quality and model adhesion. Here are some effective methods and tools for this task:

Scrapers and spatulas

- Metal or plastic scraper: Use a metal or plastic scraper to carefully pry up and remove any remaining plastic from the surface of the platform. A metal scraper is better for glass or aluminum platforms, while a plastic scraper is better for coated platforms (such as BuildTak).

- Blade: For more precise removal of small plastic residues, you can use a utility knife or razor blade.

Chemicals

- Isopropyl alcohol (IPA): Wet a cloth or tissue with isopropyl alcohol and wipe the surface of the platform. Alcohol effectively dissolves plastic residues and removes grease and dirt.

- Acetone: Acetone can be used to remove ABS plastic. Dampen a cloth with acetone and wipe the surface. Remember that acetone is not suitable for coated platforms or for removing PLA plastic.

- Special cleaning solutions: Use special 3D printer cleaning solutions that are designed to remove plastic residue from the bed.

Platform heating

Preheating: Preheat the platform to the melting temperature of the plastic (usually 60-70°C for PLA and 90-110°C for ABS). This will help soften any remaining plastic so it will be easier to remove with a scraper or putty knife.

Abrasives

Sandpaper or abrasive pads: You can use fine-grit sandpaper or abrasive pads to remove small plastic residues. Be careful not to damage the surface of the platform.

Mechanical tools

Grinders or drills with abrasive attachments: These tools can be used for thorough cleaning, but use them with care to avoid damaging the platform.

Examples of cleaning products

- BuildTak Spatula: A special spatula designed to safely remove models and plastic debris from the BuildTak platform.

- Goo Gone: Chemical remover for sticky residue and plastic. Use it in small quantities and wipe the surface thoroughly after use.

Procedure

- Heat the platform to the melting temperature of the plastic.

- Carefully pry up and remove any remaining plastic using a scraper or putty knife.

- Dampen a cloth with isopropyl alcohol or another suitable cleaning agent and wipe the surface of the platform.

- If plastic residue still remains, repeat the process or use a chemical to dissolve the plastic.

- Wipe the surface with a clean, dry cloth to remove any remaining cleaning product.

Cleaning guides and bearings

Guides and bearings ensure smooth and precise movement of the printer head. Contamination on them can cause play and reduce print quality. To clean guides and bearings:

- Use a soft cloth to remove dust and dirt.

- Apply special oil or grease to the guides and bearings to improve sliding.

To lubricate the guides and bearings of a 3D printer, it is recommended to use specialized oils and lubricants that will ensure smooth and silent movement, as well as extend the life of the components. Here are some popular options and recommendations for purchasing them:

Types of oils and lubricants

Silicone oil

- Description: Light oil that provides excellent glide and does not attract dust.

- Advantages: Does not stain, does not dry out or harden.

- Where to buy: Sold in hardware stores, auto parts stores, supermarkets and online stores.

Teflon (PTFE) grease

- Description: Synthetic grease with Teflon that provides long-term lubrication and wear protection.

- Advantages: High resistance to temperature changes, does not attract dirt and dust.

- Where to buy: Sold at hardware stores, auto parts stores, 3D printing specialty stores, and online stores.

Lithium grease

- Description: Grease, good for bearings and mechanical parts.

- Advantages: Excellent protection against wear and corrosion, durable.

- Where to buy: Sold at auto parts stores, hardware stores and online retailers.

Mineral oil

- Description: A general lubricating oil often used for sewing machines and household appliances.

- Advantages: Easily accessible, provides good glide and protection.

- Where to buy: Pharmacies, hardware stores, supermarkets and online stores.

Product examples

- Super Lube Synthetic Lubricant with PTFE: Synthetic lubricant with Teflon, available on Amazon.

- 3-IN-ONE Multi-Purpose Oil: Multi-purpose oil suitable for a variety of applications including guide and bearing lubrication.

- White Lithium Grease: Lithium grease available at auto parts and hardware stores.

- Singer All Purpose Machine Oil: Sewing machine oil available at hardware stores and online retailers.

Recommendations for use

- Cleaning Before Lubrication: Before applying lubricant, clean the guides and bearings of dust and old grease using isopropyl alcohol or another cleaner.

- Applying Oil: Apply a small amount of oil to the guides and bearings. Avoid over-lubrication as this may attract dust and dirt.

- Distribution: After applying the oil, move the carriage along the guides several times to evenly distribute the lubricant.

- Regular Maintenance: Lubricate the guides and bearings regularly to ensure smooth, quiet operation of your 3D printer.

Bearing types

If you notice the operation of your 3D printer with jerks or extraneous sounds, then most likely this is wear of the bearings! As a rule, simple cleaning may not help! Bearing wear can only be solved by replacing them!

Bearings for 3D printers are important to ensure smooth and precise movement of components. Depending on the model of your 3D printer, you may need different types of bearings. Here are the most common types of bearings and recommendations for purchasing them:

- Linear bearings (LM8UU, LM10UU, etc.)

- Description: Used for linear movement of shafts in 3D printers. The most common sizes are LM8UU (8 mm), LM10UU (10 mm), etc.

- Where to use: Used in the X, Y and Z axes to ensure smooth movement of the carriages.

- Ball bearings (608ZZ, 625ZZ, etc.)

- Description: Bearings with metal shields to protect against dust and dirt. Often used in belt drives and rollers.

- Where to use: Used in belt pulleys and extruder rollers.

- Flange bearings

- Description: Bearings with flange for easier installation and fixation.

- Where to use: Can be used in various nodes where additional fixation is required.

Where can I buy

- Online stores

- Amazon: Wide selection of bearings in various sizes and types.

- eBay: Various offers from various sellers.

- AliExpress: Budget options, but delivery may take longer.

- Specialized shops for 3D printing

- MatterHackers, FilamentOne and others: Stores that specialize in selling 3D printer components.

- Auto parts and industrial equipment stores

- Grainger, McMaster-Carr and others: Sell bearings in a variety of types and sizes.

Product examples

- LM8UU Linear Ball Bearings: Linear bearings suitable for most 3D printers. Sold in sets of 4-10 pieces.

- 608ZZ Ball Bearings: Metal shielded ball bearings often used in rollers and belt pulleys.

- F8-16M Flanged Bearings: Flanged bearings for special applications.

Recommendations for selection

- Bearing Dimensions: Make sure the bearings match the dimensions of your 3D printer. This is usually indicated in the technical documentation or on the manufacturer’s website.

- Material and Quality: Prefer bearings made from stainless steel or other durable materials for long-lasting, reliable performance.

- Reviews and ratings: When purchasing from online stores, pay attention to the seller’s reviews and ratings.

Installation recommendations

- Cleaning and Lubrication: Before installing new bearings, clean and lubricate the shafts and guides to ensure smooth sliding.

- Correct Installation: Make sure the bearings are level and secure.

- Check Movement: After installation, check the smooth movement of the carriages and shafts to ensure that the bearings are functioning correctly.

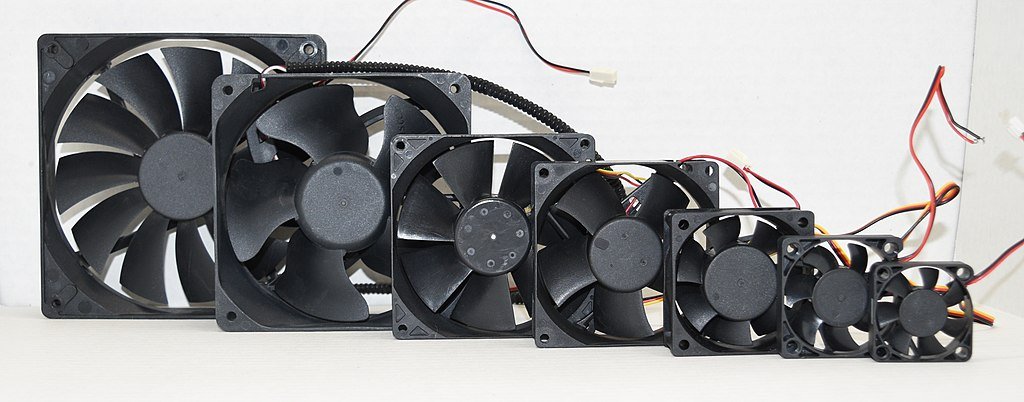

Cleaning fans and radiators

Effective cooling is important to ensure stable printer operation and prevent overheating. Dust and dirt on fans and heatsinks can reduce cooling efficiency. To clean them:

- Check the condition of fans and radiators for dust.

- Use compressed air to remove dust from fan blades and radiator fins.

You can use compressed air to blow out the fans and heatsinks of your 3D printer. Here are a few options that are suitable for this task:

Compressed air options

Compressed air cans (Aerosol Duster)

- Description: Compressed air cans are designed specifically for cleaning electronics and other delicate devices.

- Advantages: Easy to use, safe for electronics, available in various sizes.

- Where to buy: Electronics stores (Best Buy, Fry’s Electronics), office stores (Staples, Office Depot), online stores (Amazon, eBay).

Compressors

- Description: Small compressors can be used to blow air through fans and other parts of a 3D printer.

- Advantages: Can be used repeatedly, provide a stable air flow, are economical for long-term use.

- Where to buy: Auto parts stores, hardware stores (Home Depot, Lowe’s), online stores (Amazon, eBay).

Manual air pumps

- Description: Portable hand pumps or air bulbs commonly used for cleaning cameras.

- Benefits: Lightweight and portable, no electricity or batteries required, safe for sensitive parts.

- Where to buy: Photography stores (B&H Photo, Adorama), online stores (Amazon, eBay).

Product examples

- Dust-Off Compressed Gas Duster: A popular compressed air canister available in a variety of sizes.

- XPOWER A-2 Airrow Pro Multi-Use Electric Computer Duster: Electric air compressor that delivers powerful airflow.

- Giottos Rocket Air Blaster: A hand-held air blaster ideal for cleaning small parts and electronics.

If you notice that any of the fans rotates at a lower speed than the others and makes characteristic cracking sounds. This indicates an urgent fan replacement!

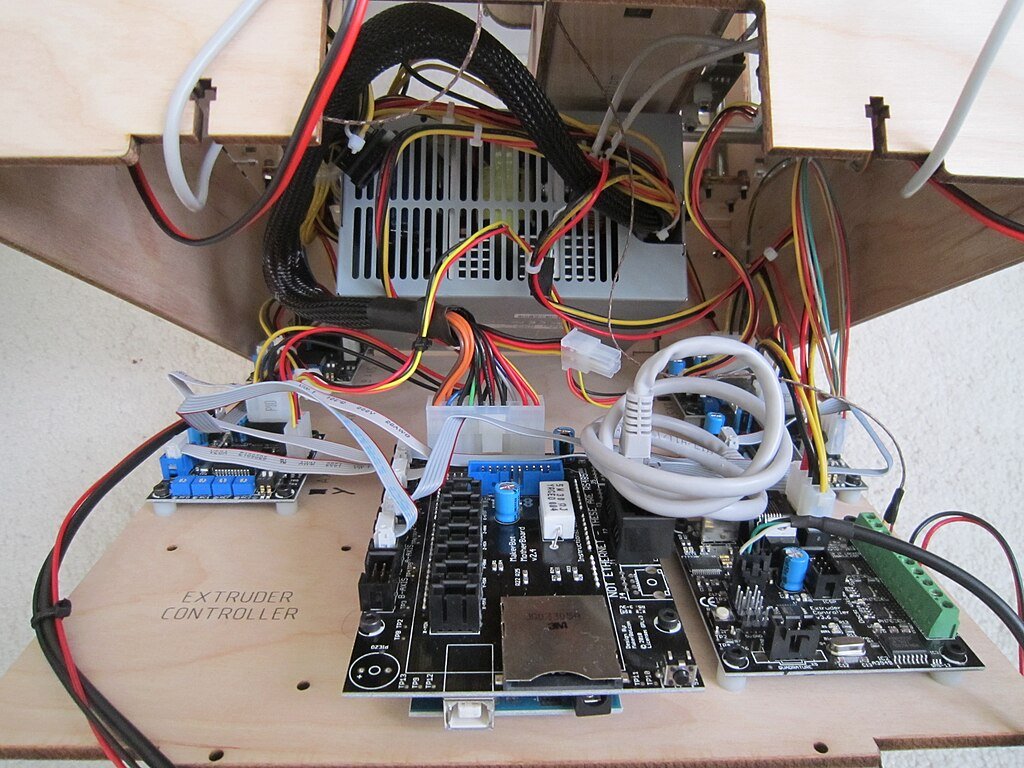

Checking and cleaning electronics

Clean electronics are the key to reliable operation of a 3D printer. Contamination on contacts and connectors can cause malfunctions. To clean electronics:

- Unplug the printer.

- Check and clean contacts and connectors from dust and dirt.

- Check the cables for damage and replace them if necessary.

To clean the contacts and connectors of a 3D printer, you can use special products that effectively remove oxidation, dirt and contaminants without damaging the contacts themselves. Here are a few options and recommendations for purchasing them:

Contact and connector cleaning products

Isopropyl alcohol (IPA)

- Description: Isopropyl alcohol is an all-purpose electronics cleaner.

- Advantages: Effectively removes dirt and oxidation, evaporates quickly, leaves no residue.

- Where to buy: Pharmacies, hardware stores, supermarkets, online stores (Amazon, eBay, AliExpress).

Contact Cleaner

- Description: Special aerosols designed for cleaning electrical contacts and connectors.

- Advantages: Evaporates quickly, safe for most materials, effectively removes contaminants.

- Where to buy: Electronics stores (Best Buy, Fry’s Electronics), hardware stores (Home Depot, Lowe’s), auto parts (AutoZone, O’Reilly Auto Parts), online stores (Amazon, eBay).

Electronics Cleaner

- Description: Aerosols and liquids for cleaning electronic components.

- Benefits: Designed for gentle cleaning and safe for use on boards and connectors.

- Where to buy: Specialized electronics stores, online stores.

Product examples

- CRC QD Electronic Cleaner: A popular contact cleaner available at hardware stores and online retailers.

- WD-40 Specialist Electrical Contact Cleaner: An effective contact and connector cleaner available at hardware stores and online retailers.

- MG Chemicals Isopropyl Alcohol: High purity isopropyl alcohol available in online stores.

Recommendations for use

- Disconnecting Power: Always unplug your 3D printer before cleaning pins and connectors.

- Using isopropyl alcohol: Dampen a soft cloth or cotton swab with isopropyl alcohol and gently wipe the pins and connectors. For hard-to-reach areas, use a soft-bristled brush.

- To use contact cleaner: Follow package directions. Typically you will need to spray the cleaner onto the pins and connectors and let them dry.

- Inspection and Assembly: After cleaning, ensure that the contacts and connectors are completely dry before plugging and turning on the device again.

Conclusion

Regular cleaning of your 3D printer will extend its life and improve print quality. We recommend cleaning the main components of the printer at least once a month or more often during intensive use. Use specialized tools and cleaning products to ensure the best care for your device.

Here are some tips to keep your favorite device working for a long time and without problems!

Regular cleaning

- Tip: Clean your printer as thoroughly as you would your teeth before a date. A clogged extruder can spoil the impression no worse than a piece of spinach on your teeth.

- Note: Regular cleaning of the extruder, platform, and fans will help prevent clogs and print quality problems.

Lubrication of guides and bearings

- Tip: Remember how mom said: “Lubricate your bicycle wheels so they don’t squeak!” It’s the same with your printer. Nobody likes things that are squeaky, especially if they’re printing your masterpieces.

- Explanation: Use silicone or Teflon oil to lubricate the guides and bearings to ensure smooth movement.

Use quality consumables

- Tip: Bad plastic is like bad ice cream: save now, but you’ll regret it later. Your printer deserves only the best!

- Explanation: Quality filament and lubricants can prevent many problems and extend the life of your printer.

Checking belt tension

- Tip: Check the tension of the straps just like you would the strings on a guitar. Poor tension results in fake music (and fake prints).

- Explanation: Check and adjust belt tension regularly to ensure accurate carriage movement.

Firmware update

- Tip: Your printer loves updates just as much as you love new episodes of your favorite TV series. Don’t leave him in the dark!

- Explanation: Updating the firmware may improve performance and resolve printer errors.

Avoid overheating

- Tip: Overheating is like summer without air conditioning. Your printer wants to be cool and fresh too!

- Explanation: Provide good ventilation and avoid overheating of components to prolong their service life.

Use a voltage stabilizer

- Tip: Bad electricity is like a bad mood: you never know when things will go wrong. The stabilizer will help avoid unexpected changes.

- Explanation: Using a voltage stabilizer will protect your printer from power surges and surges.

Regular Maintenance

- Tip: Maintain your printer as often as going to the dentist. Otherwise, unexpected problems may arise here and there.

- Explanation: Check and maintain all parts of your printer regularly to avoid unexpected problems.

Your 3D printer is not just a machine, it is your faithful assistant and friend. Take care of it, and it will delight you with flawless prints, and not surprises in the form of faulty parts. Let your printer work like a Swiss watch, and let your creations be as perfect as your care for it!