Ever tried walking a mile in someone else’s shoes? It’s not just a metaphor—most of us have experienced the discomfort of ill-fitting footwear. Enter the era of 3D printed shoes, where each step feels like walking on clouds specifically crafted for your feet. It’s like Cinderella’s glass slipper, but without the midnight curfew and, well, it won’t shatter into a million pieces if you dance too hard.

3D Printing in Fashion

3D printing is not just for making quirky desk toys or spare parts for your cousin’s drone anymore. This innovative technology has strutted its way into the fashion industry, turning heads and revolutionizing the way we think about footwear. With custom 3D footwear, designers aren’t just creating shoes—they’re crafting personalized experiences. Imagine having shoes that fit like a glove—except, you know, for your feet.

How Does it Work?

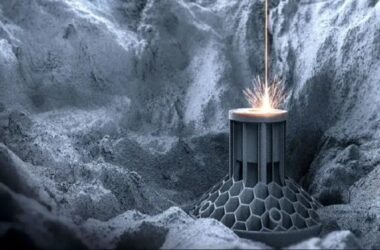

At its core, 3D printing in fashion involves using additive manufacturing to layer materials and form a solid object. For shoes, this means designers can create complex structures that are both aesthetically pleasing and functional. Think of it as building a Lego model, but instead of snapping bricks together, it’s a continuous flow of material that sculpts itself into your dream sneaker.

Innovative Shoe Design: Stepping Up the Style Game

Gone are the days when shoe design was limited to the imagination of a designer sketching in a studio. With sneaker 3D printing, the possibilities are as vast as your imagination. Here are a few ways this technology is pushing the envelope:

- Complex Structures: 3D printing allows for intricate lattice designs that would be impossible to achieve through traditional methods.

- Personalization: Each pair of shoes can be tailored to the exact specifications of the wearer, ensuring maximum comfort and style.

- Experimentation with Materials: From biodegradable plastics to flexible rubbers, designers can experiment with a range of materials to create the perfect shoe.

Talk about stepping up your style game! With advanced shoe technology, even your grandma might swap her orthopedic sneakers for a pair of these futuristic kicks. Just imagine her rocking a pair of custom 3D printed shoes at bingo night.

The Sustainable Turn: Eco-Friendly Steps

In a world that’s becoming increasingly conscious of its carbon footprint, sustainable 3D printed shoes are marching to the beat of a greener drum. Traditional shoe manufacturing can be wasteful, relying on processes that generate significant amounts of material waste. However, with 3D printing, the process is much more efficient.

The ability to produce shoes on-demand means less overproduction and waste. Plus, some companies are using recycled materials to create their products, turning what was once landfill-bound plastic into a chic pair of loafers. How’s that for turning trash into treasure?

Eco-Friendly Materials

From biodegradable plastics to plant-based polymers, the materials used in 3D printing are becoming more environmentally friendly. These innovations not only reduce the carbon footprint of shoe production but also help in creating a circular economy where materials are reused and recycled.

Personalized Footwear: The Perfect Fit

Remember the days when finding a shoe that fit perfectly was as elusive as spotting a unicorn? Well, those days are over. Personalized footwear made through 3D printing ensures that every curve, arch, and nuance of your foot is accounted for. It’s like having your own personal cobbler, minus the medieval setting and funny hat.

With the help of 3D scanning technology, companies can create a digital model of your foot, which is then used to produce a shoe that fits like a dream. And the best part? You can add your own flair, whether it’s choosing the color, texture, or even your favorite inspirational quote on the side. Who wouldn’t want to walk around with “Carpe Diem” on their sneakers?

Additive Manufacturing Shoes: The Process

The magic of 3D printing lies in its additive manufacturing process. Unlike traditional manufacturing, which often involves cutting away material to create a product, additive manufacturing builds the product layer by layer. This method not only reduces waste but also allows for greater creativity and complexity in design.

Steps in the Process

- Design: Using computer-aided design (CAD) software, designers create a digital model of the shoe.

- Preparation: The digital model is prepared for printing, including slicing the design into layers.

- Printing: The 3D printer builds the shoe layer by layer, using materials like thermoplastics or resins.

- Post-Processing: Once printed, the shoe may undergo additional finishing processes, like polishing or painting.

It’s a bit like baking a cake, but instead of flour and eggs, you’re using high-tech materials and a fancy printer. And the end result is a pair of shoes that look and feel like they were made just for you—because they were!

Advanced Shoe Technology: More Than Just a Pretty Face

The future of footwear is not just about looking good; it’s about integrating technology to improve performance and comfort. Imagine shoes that adapt to your stride, providing additional support where needed, or sneakers that monitor your running technique and provide feedback in real-time. It’s not science fiction—it’s the next step in shoe evolution.

With sensors and smart technology, 3D printed shoes can offer features that were once confined to the realm of futuristic novels. Think of it as having your own personal trainer, except it’s on your feet and doesn’t charge extra for weekend sessions.

The Future of Footwear: Where Do We Go From Here?

As 3D printing technology continues to advance, the possibilities for footwear are endless. From shoes that change color with the push of a button to those that can be completely recycled at the end of their lifecycle, the future is looking bright—and stylish.

Imagine a world where everyone has access to personalized, sustainable, and technologically advanced footwear. It sounds like a utopia for shoe lovers, and it’s closer than you might think. So, next time you’re out shopping for shoes, why not consider taking a step into the future with a pair of custom 3D printed shoes? They may just be the perfect fit for you—and the planet.